Equipment Supplied

- Coil Compactor,

- Bundling Machine,

- Strapping Machine,

- Spray Marking Machine,

- Decoiler,

- Coiler

High-speed Wire Rod Coil Compactor

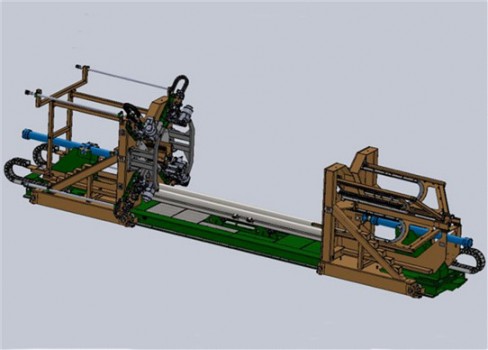

Full-automatic Horizontal Wire Compactor

Full-automatic Pp/pet Horizontal Strapping Compactor

Full-automatic Steel Strip Horizontal Strapping Compactor

Full-automatic Vertical Wire Compactor

Full-automatic Horizontal Wire Compactor:

It is mainly used for automatic binding of the metallurgical high-speed wire coil, can compress the coil hanging on the C-hook and automatically wrap and bundle the coil with the tie wire at the same time.

Equipment parameters:

|

Number of Bindings |

4 |

Pressing force |

60-400KN |

Tie wire size |

6.3-8mm |

|

Effective opening |

4700mm |

Minimum opening |

620mm |

Tie wire material |

Q195,Q235 |

|

Coil outer diameter |

Φ1400mm |

Coil inner diameter |

Φ850mm |

Binding cycle |

32s |

|

Coil weight |

2200kg |

Maximum length of C-hook |

4300mm |

Full-automatic Pp/pet Horizontal Strapping Compactor:

It is mainly used for automatic strapping of stainless steel and other products sensitive to surface scratch.

Equipment parameters:

|

Number of Bindings |

4 |

Pressing force |

60-400KN |

Strap size |

25mm,32mm |

|

Effective opening |

4700mm |

Minimum opening |

620mm |

Strap thickness |

1.2mm |

|

Coil outer diameter |

Φ1400mm |

Coil inner diameter |

Φ850mm |

Strap material |

PP/PET |

|

Coil weight |

2200kg |

Maximum length of C-hook |

4300mm |

Binding cycle |

32s |

Full-automatic Steel Strip Horizontal Strapping Compactor:

Equipment parameters:

|

Number of Bindings |

4 |

Pressing force |

60-400KN |

Strap size |

32mm |

|

Effective opening |

4700mm |

Minimum opening |

620mm |

Strap thickness |

0.8-1.0mm |

|

Coil outer diameter |

Φ1400mm |

Coil inner diameter |

Φ850mm |

Strap material |

Steel |

|

Coil weight |

2200kg |

Maximum length of C-hook |

4300mm |

Binding cycle |

32s |

Full-automatic Vertical Wire Compactor:

It is mainly used with the vertical pallet transport system and occupies a small area.

Equipment parameters:

|

Number of Bindings |

4 |

Pressing force |

60-400KN |

Tie wire size |

6.3-7mm |

|

Effective opening |

3700mm |

Minimum opening |

550mm |

Tie wire material |

Q195,Q235; |

|

Coil outer diameter |

Φ1250mm |

Coil inner diameter |

Φ850mm |

Binding cycle |

35s |

|

Coil weight |

2200kg |

Pallet height |

3300mm |

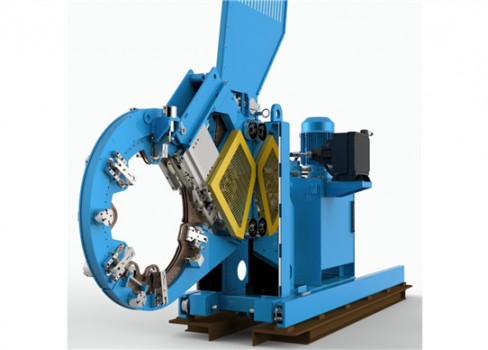

Bar Bundling Machine

Single-track Bar Bundling Machine

Double-track Bar Bundling Machine

Double-track Aluminum Bar Bundling Machine

Single-track Bar Bundling Machine:

It is used for tying bundles of round rod, re-bar, flat steel and angle steel.

The bundling machine is installed in a fixed position beside the roller table, and the bar bundle passes through the closed wire track system when passing the roller table.

Features:

High reliability

twist head and guide system

knot push down

Full-automatic control

Equipment parameters:

|

Number of wraps |

Single-wind single-knot |

Tightening force |

9 KN |

Tie wire size |

6.3-8 mm |

| Bar bundle size |

Φ150-550 mm; |

Valve voltage |

24 V |

Tie wire materials |

Steel wire Q195, Q235; |

| Inner diameter of wire track |

Φ700 |

Motor power |

11 KW |

Binding cycle |

Single winding for 7 s |

|

Hydraulic system pressure |

100 bar |

Pump capacity |

100 l/m |

Double-track Bar Bundling Machine:

It is used for tying bundles of round rod, re-bar, flat steel and angle steel.

The bundling machine is installed in a fixed position beside the roller table, and the bar bundle passes through the closed wire track system when passing the roller table.

Features:

High reliability

double turn twist head and guide system

knot push down

Automatic single and double winding mode switching

Full-automatic control

Equipment parameters:

|

Number of wraps |

Single winding and single knot or double winding and single knot |

Tightening force |

9KN |

Tie wire size |

6.3-8mm |

|

Bar bundle size |

Φ150-450mm;Φ150-550mm; |

Valve voltage |

21V |

Tie wire material |

Steel wire Q195,Q235; |

|

Inner ring diameter of wire track |

Φ700,Φ900; |

Motor power |

11KW |

Binding cycle |

Single winding 7s; Double winding 10s |

|

Hydraulic system pressure |

100bar |

Pump capacity |

100l/m |

High reliability

Double-track Aluminum Bar Bundling Machine:

It is mainly used for the full-automatic bundling of aluminum bar and other products sensitive to surface scratch.

Equipment parameters:

|

Number of wraps |

Double winding and single knot |

Tightening force |

9KN |

Tie wire size |

6.3-8mm |

|

Bar bundle size |

Φ150-450mm;Φ150-550mm; |

Valve voltage |

21V |

Tie wire material |

Aluminum wire |

|

Inner ring diameter of wire track |

Φ700,Φ900; |

Motor power |

11KW |

Binding cycle |

Double winding 10s |

|

Hydraulic system pressure |

100bar |

Pump capacity |

100l/m |

H-beam tying machine

H-beam Tying Machine

H-beam Tying Machine:

It is used to complete the bundling of square bundles

The bundling machine is mounted in a fixed position on the roller table, and the bar bundles pass through the roller table and also pass through the closed lane system of the bundling machine.

Features:

Top orientation, offset to corner twist head

Water drop shape tie wire guide

Anti-scratch roller arrangement

Equipment parameters:

|

Number of wraps |

Single winding and single knot |

Tightening force |

9KN |

Tie wire size |

6.3-8mm |

|

Max. square bundle size |

1000X1000mm; |

Valve voltage |

21V |

Tie wire material |

Steel wire Q195,Q235; |

|

Effective opening of wire track |

1500X1300mm |

Motor power |

11KW |

Binding cycle |

10s |

|

Hydraulic system pressure |

100bar |

Pump capacity |

100l/m |

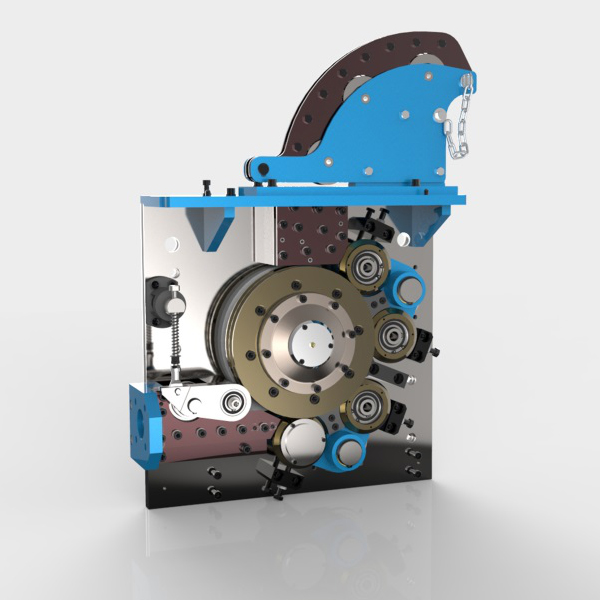

Strapping Machine

Full-automatic Circumferential Strapping Machine

Full-automatic Radial Strapping Machine

Semi-automatic Circumferential Strapping Machine

Semi-automatic Radial Strapping Machine

Full-automatic Circumferential Strapping Machine:

1) Strip coil circumferential strapping machine — side strapping (single head/double head)

● Installed at the coiler outlet or the position where the strip coil direction is the same as the conveying direction

● Applicable strip coil width: 550~2000mm

●Applicable strip coil outer diameter: 900~2250mm

● Strapping condition: 1~3 pieces/ 1~5 tracks

2) Strip coil circumferential strapping machine — top strapping

● Installed on the transport line where the strip coil direction is perpendicular to the conveying direction

● Applicable strip coil width: 550~2000mm

● Applicable strip coil outer diameter: 900~2250mm

● Strapping condition: 1~5 tracks

3) Long product strapping machine — top strapping

● Suitable for online bundling of section steel, steel pipe, bar, etc.

● Applicable stack width: 150~550mm

● Applicable stack height: 150~600mm

● Tailor made engineering is available.

Full-automatic Radial Strapping Machine:

Installed on the transport line where the strip coil direction is the same as the conveying direction

Applicable strip coil width: 550~1800mm

Applicable strip coil outer diameter: 900~2000mm

Applicable strip coil inner diameter: >740mm

Strapping condition: 1 track

Semi-automatic Circumferential Strapping Machine:

Installed at the coiler outlet or the position where the strip coil direction is the same as the conveying direction

Applicable strip coil width: 950-2350mm

Applicable strip coil outer diameter: 900-2650mm

Strapping conditions: 1-5 tracks

Semi-automatic Radial Strapping Machine:

Installed on the transport line where the strip coil direction is the same as the conveying direction

Applicable strip coil width: 550~1800mm

Applicable strip coil outer diameter: 900~2000mm

Applicable strip coil inner diameter: >740mm

Strapping conditions: 1 track

Spray Marking Machine

Single-nozzle Spray Marking Machine

Single-nozzle Spray Marking Machine:

Controlled by advanced robots, it can continuously print marks on the surface of cold-rolled and hot-rolled strip coils and is featured with extremely strong mechanical stability and high-speed spray printing.

The single-nozzle strip coil spraying robot has been widely used in many steel mills for many years, and it has been proved that it has very stable performance even in the worst working environment.

Under the control of the robot, combined with special paint spraying nozzle and heat protection device, mark spraying can be performed on the surface of cold-rolled and hot-rolled strip coils by using non-toxic and non-blocking paint. The mark spraying machine may be used to measure the size of the steel coil, spray marks on the surface of the strip coil in the form of a straight line or a curve, and may also be used to spray one or more lines of marks on the end face of the coil when necessary.

Features:

Full-automatic printing (marking)

Flexible operation with advanced robots

Free programmable

Application of non-toxic, non-clogging paint

Paint (ink) level indication and alarm

Easy to install, suitable for existing and new production lines

Low maintenance costs

Equipment parameters:

| Time for spray printing of characters |

1.0 second / character |

Character height |

50-100mm |

Ink color |

White |

|

Strip coil diameter |

Max. Φ2800mm |

Strip coil width |

Max.2200mm |

Strip coil temperature |

750℃ |

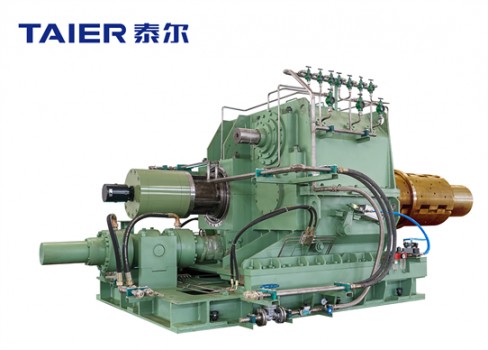

Decoiler/Recoiler

Decoiling

Recoiling

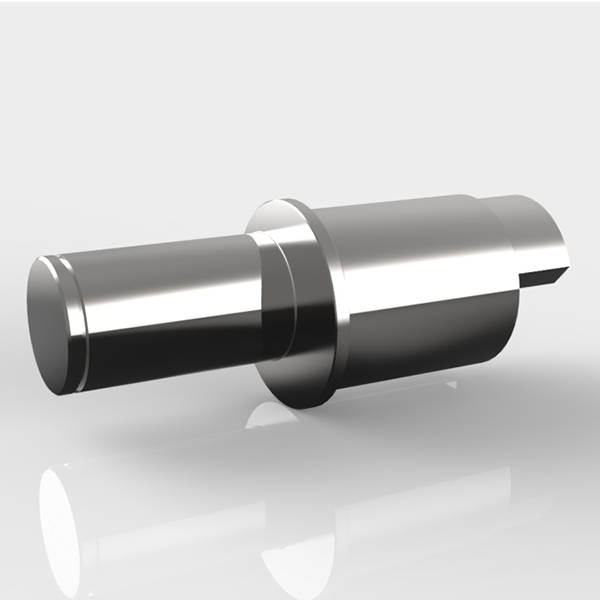

Decoiling:

Located at the starting end of the production line and used for unwinding the coiled strip.

- Use of cantilever type mandrel;

- Mandrel expansion and contraction driven by the rotary hydraulic cylinder;

- With CPC alignment function;

- The reducer is lubricated with thin oil;

Technical parameters of product:

Recoiling:

Located at the end of the strip production line and used for winding the strip.

- Use of cantilever type mandrel;

- Mandrel expansion and contraction driven by the rotary hydraulic cylinder;

- EPC edge flush coiling;

- The reducer is lubricated with thin oil;