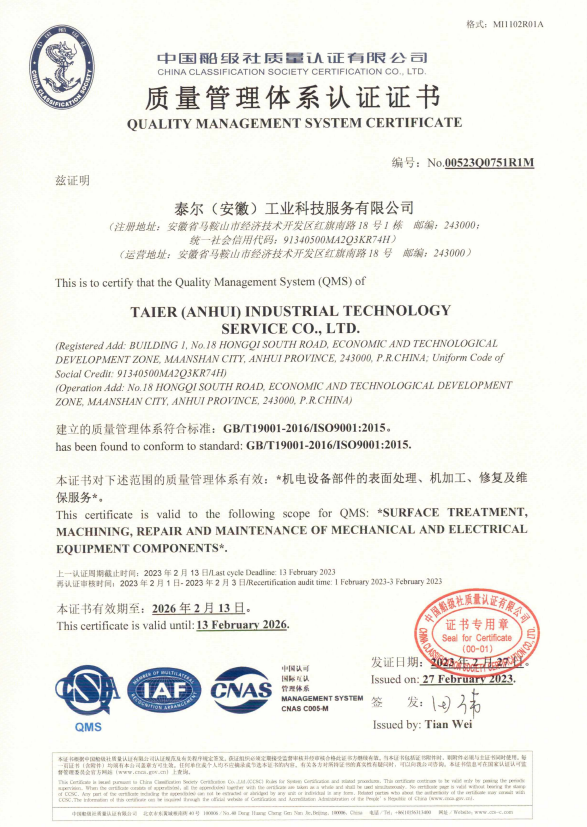

Quality Management System

Quality policy: customer-centered, system management; continuous improvement to meet and exceed customer requirements.

Introduction of the Test Center

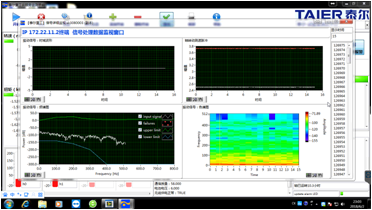

Introduction of On-line Monitoring

The on-line monitoring system can collect the working status of the coupling and its related parameters in real time by installing a sensor and auxiliary components on the coupling, and manage the collected data or information with corresponding software to realize real-time data query, historical data query, overload fault alarm, event management, management of coupling-related information and other functions, meanwhile, it can display and demonstrate these data via the client-side, facilitate the field equipment management personnel to master the running condition information of the coupling or provide data support for the determination of abnormal faults, in addition, it can feed back the spot check information through the mobile phone client to provide information for inspection and recording of the site personnel.

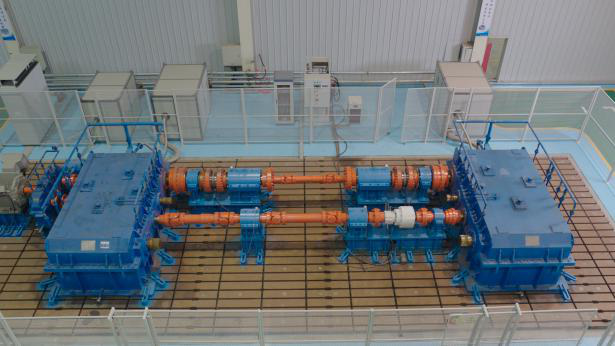

Introduction of The Test Platform

The laboratory has three sets of comprehensive performance test benches for coupling: operating characteristics test bench (highest test speed of 2000 r/min, maximum dynamic load test torque of 400kN•m, maximum closed power of 3600kW, maximum allowable swing angle of 15°), 1# static load test bench (maximum static test torque of 12000kN•m, maximum allowable swing angle of 5°), 2# static load test bench (maximum static test torque of 800kN•m, without swing angle), and is provided with a variety of advanced professional instruments, equipment and software including Germany SIEMENS high power electric drive equipment, Germany GAT internally-suspended hydraulic torque loader, Germany HBM high-precision torque sensor, US NI data acquisition system and its I/O module.

The first test platform in China.

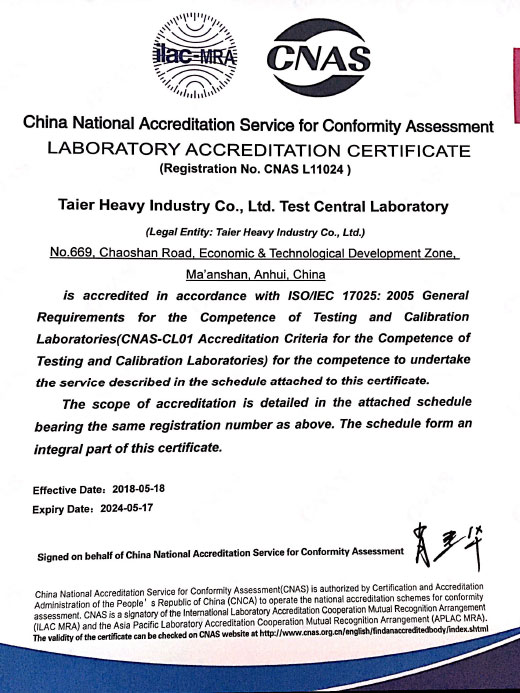

Introduction of The Testing Room

The testing room is a comprehensive testing room mainly engaged in the testing and analysis of the chemical composition, mechanical properties, metallographic testing, non-destructive testing, 3D, etc. of metal materials and their products. The testing room covers an area of more than 400m2, has more than 40 sets of scientific and testing equipment with domestic and international advanced level, and has comprehensive analytical capabilities from physics to chemistry and from macro to micro. On May 18, 2018, the test center was accredited by the China National Accreditation Service for Conformity Assessment (CNAS).

Service Items

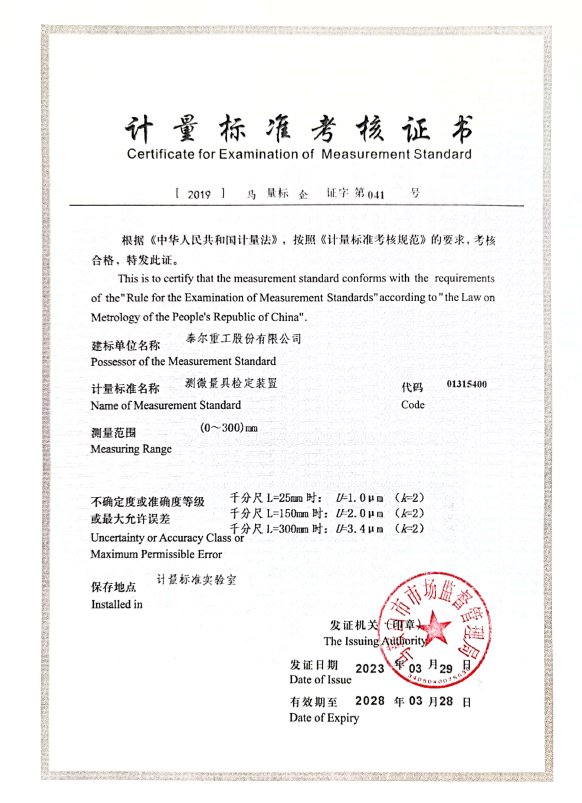

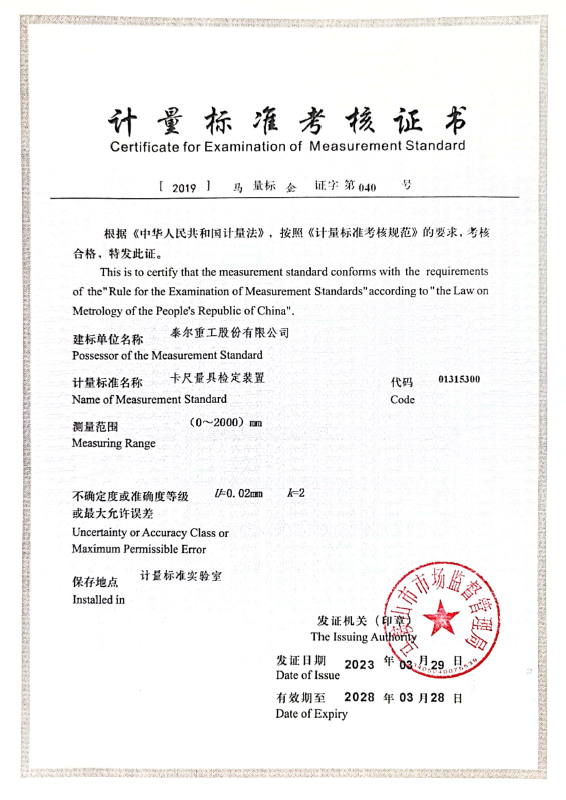

Metrology Calibration/Verification

Testing and Inspection