Cold Rolling Equipment

Strip Reversing Mill Stand:

Single-stand reversing cold rolling mill unit is used to process the pickled and trimmed hot-rolled coil of carbon steel with various materials and a thickness of 1.2~6.0mm (under normal temperature) into cold-rolled coils of various specifications with required thickness and surface roughness through several times of rolling. We can reasonably configure the units according to the customer’s demand for finished strip steel.

Basic Configurations of The Unit:

| Unit NameTechncial Specification | 900 single-stand reversing cold rolling mill unit | 1200 single-stand reversing cold rolling mill unit | 1250 single-stand reversing cold rolling mill unit | 1450 single-stand reversing cold rolling mill unit | 1500 single-stand reversing cold rolling mill unit | |

| Form | Single-stand reversing (6-roll) | Single-stand reversing (6-roll) | Single-stand reversing (20-roll) | Single-stand reversing (6-roll) | Single-stand reversing (6-roll) | |

| Nominal capacity | 80,000 tons / year | 200,000 tons / year | 75,000 tons / year | 250,000 tons / year | 250,000 tons / year | |

| Maximum rolling speed | 1200 m/min | 1200 m/min | 800 m/min | 1200 m/min | 1200 m/min | |

|

Rolled material |

Material | Q195-Q345, 08AL, IF | Q195-Q345, 08AL, IF | Carbon structural steel, high quality carbon structural steel, low alloy steel | Low carbon steel, medium carbon steel, low alloy steel, electrical steel | Plain carbon steel, high quality carbon steel, low alloy steel |

| Plate thickness (in/out) | 1.8-4.0/0.2-1.25mm | 1.5-3.0/0.2-0.8mm | 0.35-3.1/0.12-1.2mm | 1. 5-3/0.35-2.0mm | 1. 8-2.0/0.2-0.65mm | |

| Plate thickness | 450-750mm | 600-110mm | 700-1100mm | 900-1300mm | 900-1350mm | |

| Coil weight | 8t | 20t | 20t | 25t | 25t | |

| Rolling force | 9MN | 15MN | 6MN | 18MN | 20MN | |

Five-stand Cold Continuous Rolling Mill Unit:

Five-stand cold continuous rolling mill unit is used to process the pickled and trimmed hot-rolled coil of carbon steel with various materials and a thickness of 1.2~6.0mm (under normal temperature) into cold-rolled coils of various specifications with required thickness and surface roughness through rolling of five stands. We can reasonably configure the units according to the customer’s demand for finished strip steel.

Basic Configurations of The Unit:

|

Unit NameTechncial Specification |

1250 pickling continuous cold rolling mill unit |

1420 pickling continuous cold rolling mill unit |

1450 pickling continuous cold rolling mill unit |

1550 pickling continuous cold rolling mill unit |

1780 pickling continuous cold rolling mill unit |

|

|

Form |

Six-stand continuous rolling |

Six-stand continuous rolling |

Five-stand continuous rolling |

Five-stand continuous rolling |

Five-stand continuous rolling |

|

|

Nominal capacity |

870,000 tons / year |

1,000,000 tons / year |

600,000 tons / year |

1,100,000 tons / year |

1,500,000 tons / year |

|

|

Maximum rolling speed |

1700 m/min |

1700 m/min |

400 m/min |

1350 m/min |

1350 m/min |

|

|

Rolled material |

Material |

CQ, DQ, HSS |

CQ, DQ, HSS |

Stainless steel |

Hot-rolled low carbon steel, ultra low carbon steel, etc. |

Q195, Q235, 45# |

|

Plate thickness (in/out) |

2.0-4.5/0.18-2.0mm |

2.0-4.5/0.18-2.0mm |

2. 0-6.0/0.2-2.0mm |

2. 0-6.0/0.3-3.0mm |

||

|

Plate thickness |

700-1100mm |

700-1300mm |

750-1320mm |

750-1430mm |

800-1630mm |

|

|

Coiler weight |

22t |

25t |

28t |

28.6t |

30t |

|

|

Rolling pressure |

18MN |

20MN |

20MN |

22MN |

25MN |

|

Hot Rolling Equipment

The leader of heavy plate and hot strip mill equipment upgrade

We have a solution design team and a project management team that masters core technology of complete set of technical equipment for hot-rolled strips, and are concentrated on the upgrading and reconstruction of complete set of technical equipment for strips including hot continuous rolling, wide and thick plate and steekle mill. We hold the full-life cycle service concepts of providing complete set of equipment upgrading and reconstruction from traditional spare parts to customized equipment for all customers through integrated solution of process, machine, electricity, liquid as well as advanced and quality services.

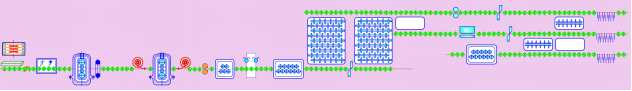

Hot continuous rolling production line

Typical production line specification: 1000mm, 1250mm, 1450mm, 1580mm, 1780mm, 2050mm, 2150mm, 2250mm

Production demonstration:

Steekle furnace rolling mill line

Typical production line specifications: 1780mm, 2250mm, 3500mm, 4300mm

Production demonstration:

Medium plate, wide and thick plate production line

Typical production line specifications: 2500mm、2800mm、3500mm、3800mm、4300mm、5000mm

Production demonstration: