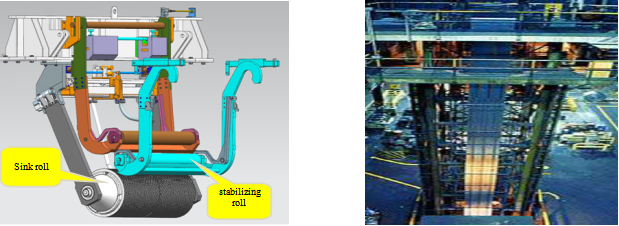

Sink Roll And Stabilizing Roll Series

Zinc pot is the key equipment of the cold-rolling continuous hot-dip galvanizing unit, among them, the “three rolls” (sink roll, stabilizing roll and guide roll) are core components in the zinc pot. The “three rolls” are immersed in the molten zinc solution for a long time, and different forms of zinc slags such as Zn-Fe, Fe-Al and Fe-Zn-Al are inevitably present in the zinc liquid, therefore, the surface quality of the “three rolls” will directly affect the quality and yield of the strip ste...

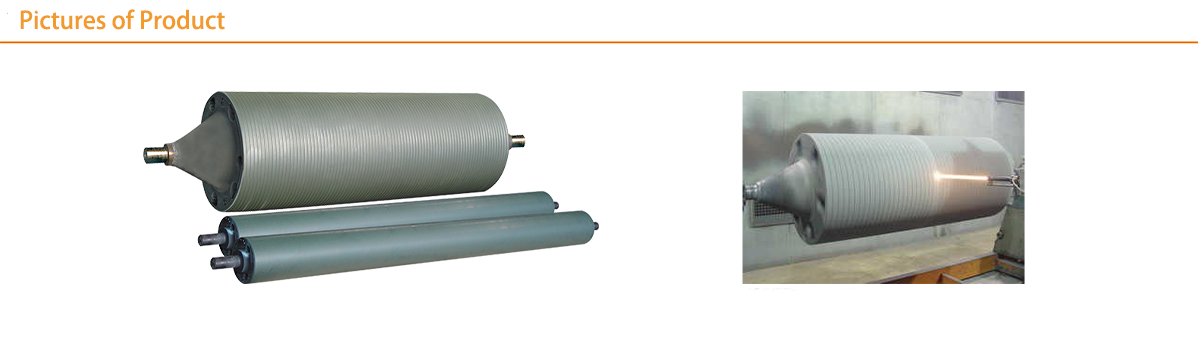

Zinc pot is the key equipment of the cold-rolling continuous hot-dip galvanizing unit, among them, the “three rolls” (sink roll, stabilizing roll and guide roll) are core components in the zinc pot. The “three rolls” are immersed in the molten zinc solution for a long time, and different forms of zinc slags such as Zn-Fe, Fe-Al and Fe-Zn-Al are inevitably present in the zinc liquid, therefore, the surface quality of the “three rolls” will directly affect the quality and yield of the strip steel, which is especially true in the production of top-grade automobile outer sheet. The sink roll and stabilizing roll manufactured by Anhui Taier Surface Engineering Technology Co., Ltd. is characterized by high cost performance, long service life, etc. The surface ceramic coatings of the sink roll, stabilizing roll and guide roll made with internationally advanced high-velocity oxygen-fuel (HVOF) technology are featured with high wear resistance and strong resistance to zinc liquid corrosion; the anti-adhesion performance of roll surface is enhanced through the treatment of specially-developed surface sealing technique; meanwhile, with optimized design and fabrication of the sink roll surface groove and control of the stabilizing roll surface microstructure, the slag discharge performance and the resistance to viscous slag are greatly improved. With the upgrading of user products and the continuous improvement of strip quality requirements, the experts with rich experience of Anhui Taier Surface Engineering Technology Co., Ltd. will provide you with personalized service and system solutions in all aspects and create value for your success based on the conditions of customer set.

| Service condition: |

Zn-Al liquid/460±5℃,speed≤200m/min |

Coating process: |

HVOF/sealed |

| Failure mode: | Corrosion, wear, peeling |

Coating material: |

Metallic ceramic |

| Performance requirements: | Resistance to molten zinc solution corrosion, wear resistance, high bonding strength | Service life indicator: |

Life of coating: 40-60 days |