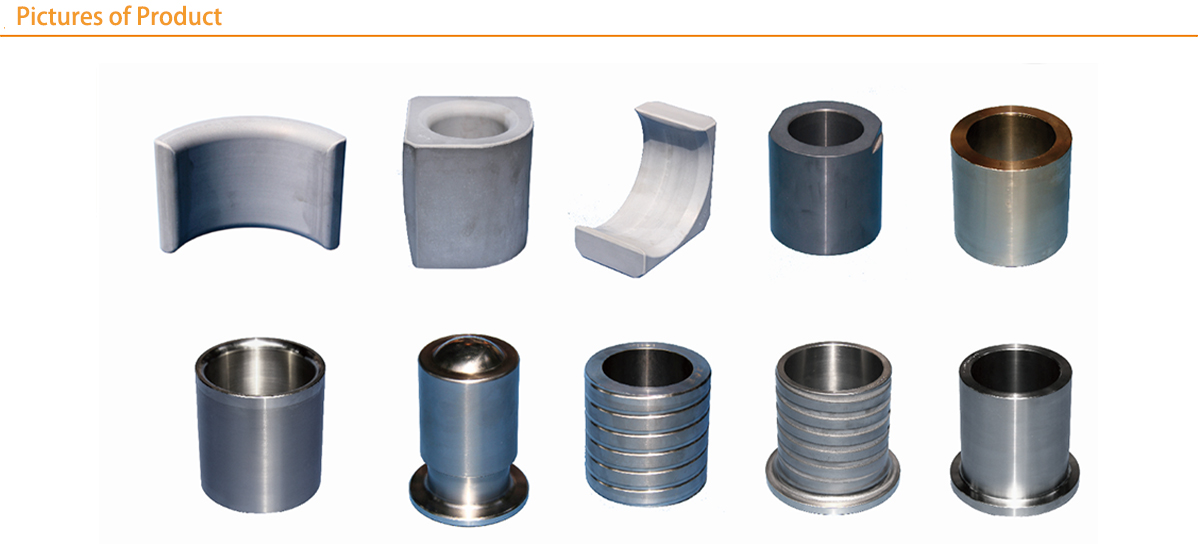

Cold-rolled Hot-dip Galvanized Shaft Sleeve And Bush

Cold-rolled Hot-dip Galvanized Shaft Sleeve And Bush

The sleeve and bushing, are the key parts for a cold rolling hot galvanization line, are installed on the heads and arms of the sink roll and the stabilizing roll and used to serve as the drive bearings of these rolls. They must tolerate the challenge from high temperature, corrosion by molten zinc and abrasion. For this reason, traditional products have the disadvantages of a short service life, poor stability and high comprehensive cost. With advanced materials and special process, we have developed the sleeve and bushing series with a broad range of advantages like resistance against high temperature, resistance against abrasion and stable operation. They can effectively help customers improve product quality and reduce the comprehensive cost, thereby satisfying customer demands for different production lines.

|

List of Series Products of Surface Sleeve and Bush of Taier |

||||

|

Product Number |

Hardness match sleeve-bushing |

Characteristics |

Target market |

Product feature |

|

TAIER01 |

HRC60- ceramic |

Shaft sleeve:★★★★★ Bushing: ★★★★★ |

Premium car panel、home appliance plate lines | Good stability、Long service life、High cost performance、Leading international |

|

TAIER02 |

HRC60—HRC45 |

Shaft sleeve: ★★★ Bushing: ★★★★ |

Medium-to high-end car panels、home appliance plate lines | Good stability、High cost performance、The domestic leading |

|

TAIER03 |

HRC45- ceramic |

Shaft sleeve:★★★★★ Bushing: ★★★ |

Medium-to high-end car panels、home appliance plate lines | Good stability、High cost performance、Replace imported |

|

TAIER04 |

HRC40—HRC45 |

Shaft sleeve: ★★★ Bushing: ★★★ |

common car panel、home appliance plate lines | Moderate price and outstanding performance |

|

TAIER05 |

HRC30—HRC35 |

Shaft sleeve: ★ Bushing: ★ |

Building plate line (tension of zinc pot<500 Kg) | Low price |

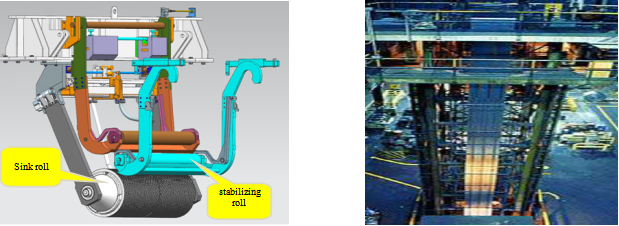

Sink Roll And Stabilizing Roll Series

Sink Roll And Stabilizing Roll Series

Zinc pot is the key equipment of the cold-rolling continuous hot-dip galvanizing unit, among them, the “three rolls” (sink roll, stabilizing roll and guide roll) are core components in the zinc pot. The “three rolls” are immersed in the molten zinc solution for a long time, and different forms of zinc slags such as Zn-Fe, Fe-Al and Fe-Zn-Al are inevitably present in the zinc liquid, therefore, the surface quality of the “three rolls” will directly affect the quality and yield of the strip steel, which is especially true in the production of top-grade automobile outer sheet. The sink roll and stabilizing roll manufactured by Anhui Taier Surface Engineering Technology Co., Ltd. is characterized by high cost performance, long service life, etc. The surface ceramic coatings of the sink roll, stabilizing roll and guide roll made with internationally advanced high-velocity oxygen-fuel (HVOF) technology are featured with high wear resistance and strong resistance to zinc liquid corrosion; the anti-adhesion performance of roll surface is enhanced through the treatment of specially-developed surface sealing technique; meanwhile, with optimized design and fabrication of the sink roll surface groove and control of the stabilizing roll surface microstructure, the slag discharge performance and the resistance to viscous slag are greatly improved. With the upgrading of user products and the continuous improvement of strip quality requirements, the experts with rich experience of Anhui Taier Surface Engineering Technology Co., Ltd. will provide you with personalized service and system solutions in all aspects and create value for your success based on the conditions of customer set.

| Service condition: |

Zn-Al liquid/460±5℃,speed≤200m/min |

Coating process: |

HVOF/sealed |

| Failure mode: | Corrosion, wear, peeling |

Coating material: |

Metallic ceramic |

| Performance requirements: | Resistance to molten zinc solution corrosion, wear resistance, high bonding strength | Service life indicator: |

Life of coating: 40-60 days |

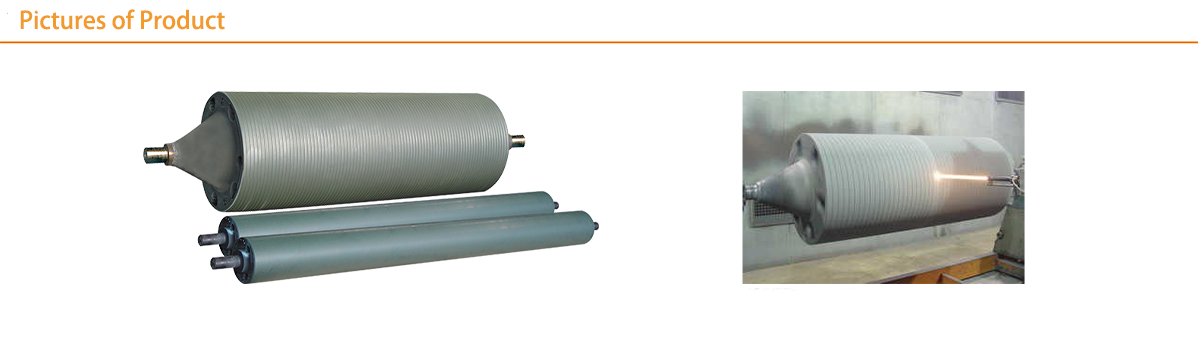

Furnace Roll Series

Furnace Roll Series

Furnace roll is a core component in cold rolling continuous annealing unit and continuous hot-dip galvanizing unit annealing furnace. Due to long-term service at high temperature, in addition to having excellent heat resistant performance including high strength, strong resistance to high temperature oxidation corrosion, good wear resistance and excellent thermal shock resistance, the furnace roll surface coating must have excellent ability to resist accumulated burl (accumulated burl of Fe for ordinary steel and accumulated burl of Mn for high-strength steel) to ensure the quality of strip steel, long-term roughness retention performance and the establishment of tension in the furnace. Anhui Taier Surface Engineering Technology Co., Ltd. adopts international advanced continuous spraying technology including HVOF and plasma arc, the high temperature superalloy + ceramic coating manufactured has the advantages of long service life and high cost performance, and advanced post treatment equipment and technology can be used to manufacture the furnace rolls of various roll types and different roughness.

| Service condition: |

Temperature ≤1,100℃, N2 + H2 |

Coating process: |

APS, HVOF/sealed |

|

Form of ageing: |

Scaffolding, abrasion, crack and corrosion |

Coating material: |

NiCr-CrC、MCrAlY+Al2O3、MCrAlY+ZrB2 |

|

Property requirement: |

Resistant to high temperature tumor、 abrasion and heat shock |

Service Life indicator: |

≥3 years |

Process Roll Series

Process Roll Series

The process roll is widely used in all cold rolling units and generally work in the atmospheric environment, mainly including: turning roll, correction roll, tension roll, tension meter roll, loop back roll, etc., and it is mainly used for transmission, correction and tension adjustment of strip, therefore, it is required that the roll surface shall have good wear resistance and tension retention performance, etc. the roll surface is in direct contact with the strip, therefore, the coating surface properties will directly affect the quality of the strip. To meet the needs of process roll surface of different cold rolling units and different locations, Anhui Taier Surface Engineering Technology Co., Ltd. adopts advanced HVOF and post-treatment technology of coating to obtain the characteristics from mirror surface to the process roll surface with high roughness. Advanced technology ensures that the roller has excellent wear resistance and roughness retention performance, and properly solves the problem of adhesion of foreign matter on the roll surface, thus meeting the user’s requirements for high cost performance, long service life, high efficiency and high quality of the process roll.

| Service condition: |

Atmosphere/constant temperature/HSS hot galvanization line |

Coating process: |

HVOF, overlaying + HVOF/quenching + HVOF |

| Failure mode: | Wear, peeling, foreign matter adhesion |

Coating material: |

Metallic ceramic/alloy steel + Metallic ceramic |

| Performance requirements: | Wear resistance, high bonding strength, resistance to foreign matter crushing |

Life indicator: |

Improved by more than 3 times compared with Gr galvanized roll |

Side Guide of Hot Rolling Production Line

Side Guide of Hot Rolling Production Line

The side guide is also called guide, which is an important part of the hot rolling production line and is used to ensure the stability and directionality of the hot-rolled strip during traveling (especially before coiling), generally, there is a group or many groups of side guides. During operation of the hot rolling unit, the high-temperature and high-speed hot-rolled sheet contacts and rubs with the side guide, which results in are serious wear of the contact part and cause such quality problems as burrs and scratch on the edge of the hot-rolled sheet. The wear loss of the side guide made of conventional carbon steel is 10-15mm a day, which results in replacement and repair of the side guide of the hot rolling unit every day.

The amorphous composite ceramic coating fabricated by our company with advanced plasma cladding technology has excellent normal temperature hardness and high temperature hardness, meanwhile, with optimized chemical composition of the material, the friction coefficient is effectively reduced and the wear-resisting property of the material is greatly improved. The product is characterized by domestic-leading and international-advanced technology, and the side guide manufactured has a service life of up to 5-7 days.

Excellent cost performance

- Reduce the workload at the production site

Replacement made once a day is improved to once every 5-7 days, the workload for replacement of the maintenance personnel is reduced and repair welding is eliminated; the site is released and the amount of spare parts for the side guide is reduced.

- Reducing wear and improving product quality

The groove depth of long-life side guide decreases after wear, reducing the damage to the hot rolling strip and improve the quality of the hot rolling strip product.The wearing depth of carbon steel side guide is more than 5 mm per day, and can even reach 10-15 mm.The total wearing depth of side guides adopted with new technology can be reduced to 1 mm per day.

- Improving the output of hot rolling production line

The reduction of replacement frequency is beneficial to the increase of field production. If the service life of side guide is increased from 1 day to 5 days, the production time of the hot rolling production line may be increased by 8 hours every month. Taking the 1780 hot rolling production line as an example, at least 1,000 tons of hot-rolled sheets may be increased per year.

Ø Reduce the workload at the production site

Laminar Cooling Roll

Laminar Cooling Roll

Laminar cooling roll is installed between the finishing mill and the recoiler which is used in hot strip rolling mill. The temperature of the strip is tightly controlled by water cooling to ensure the normal operation of the coiling. The laminar cooling roll is mainly divided into the inner cooling roll and the outer cooling roll. When the hot rolling mill is in operation, friction between hot rolling strip at high temperature and high speed and roll ,and the cooling roll surface is subjected to repeated erosion and cooling of the circulating water. The main failure types of the conventional laminar cooling roll are wear of roll surface, corrosion, roll surface peeling, and roller drive chain failure.

The high-performance laminar cooling roll developed by our company adopts advanced laser cladding technology. The roll surface has excellent wear resistance and corrosion resistance. The hardened layer and the roll body are metallurgical bonding with high bonding strength. At the same time, by optimizing and improving the material and structure and the strength of the cooling roll is well improved, the phenomenon of water ingress and jamming of the bearing is effectively prevented, and the service life and reproducing times are also improved. The product technology reaches leading position both at home and abroad. The service life of the laminar cooling roll surface is twice that of the roll adopting spray welding process.

Excellent cost performance:

Excellent hardened layer performance

By utilizing the laser cladding technology characterized by rapid thermal and rapid cooling, the working procedure of preheating and annealing are eliminated. The temperature of substrate is lowered to reduce the heat affect of the work-piece. The cladding layer and the substrate are highly metallurgical bonding. The cladding layer is finely organized without fine pores, and it has excellent wear resistance and corrosion resistance.

Stability & Reliability

The roll body and the spindle head are made of higher strength material. Screw cutting, sand blasting and remelting are not required in the preparation process of the coating, which significantly improves the use intensity. of the cooling roll. Through the optimization and improvement of the bearing seal structure, the phenomena of bearing water ingress and jamming are effectively prevented.

The quality of strip steel is improved and the environmental pollution is reduced

The service life of the roller itself is extended because of its excellent wear resistance and corrosion resistance, which better improve the surface quality of the strip steel product. The production process of our company high-performance laminar cooling roll has low energy consumption and meets the requirements of green manufacturing without environmental pollution.

Crystallizer for Continuous Casting

Crystallizer for Continuous Casting

The crystallizer in the continuous casting unit is a bottomless steel ingot mould of forced water cooling, which is usually called the “heart” of continuous casting equipment and is mainly used to make the molten steel gradually solidified into the slab shell of required size and shape and ensure uniform, stable and continuous generation of the slab shell. Crystallizer copper plate is the core component in this “heart”, the surface of the copper plate is in direct contact with the molten steel, and the friction with the surface of copper plate is intensified after the molten steel is solidified into the slab shell, plus the corrosion by the protective slag, therefore, the copper plate surface shall have good resistance to thermal cracking, wear and corrosion. The crystallizer copper plate manufactured by Anhui Taier Surface Engineering Technology Co., Ltd. is a coating resistant to high temperature, wear and corrosion that is made with advanced HVOF, and its main components are high temperature alloys or high temperature alloys + ceramics and other materials. The excellent properties of the coating material ensure that the copper plate can work at high drawing speed and the total amount of steel used at one time is significantly improved, reducing the overall cost for operation of the user equipment and the increase of the unit output.

| Service condition: | Temperature of contact surface with liquid steel ≤500℃ | Coating process: | HVOF/Remelting |

| Failure mode: | Wear, crack, corrosion | Coating material: | Wear-resistant alloy |

| Performance requirements: | Wear resistance, corrosion resistance, good thermal conductivity | Life indicator: | Improved by 4-6 times compared with electro-galvanized Ni |