Rolling Zeb Housing Ncej - Laser cladding Remanufacturing

Rolling Zeb Housing Ncej - Laser cladding Remanufacturing

Dov zeb tsev nyob ncej tseem hu ua dov zeb muag zaub, uas yog siv rau nruab rau hauv lub menyuam, cov menyuam tau cov kabmob, cov menyuam hloov ntaus ntawv, coj cov khoom, thiab lwm yam thiab kuj yog ib qho tseem ceeb heev load-nqa tivthaiv nyob rau hauv lub dov cov khoom. Nws yog feem ntau yog ua los ntawm zoo tib yam steel castings thiab nws casting txheej txheem txiav txim hais tias lub cev nto tsis muaj siab zog, corrosion kuj thiab lwm yam kev ua tau zoo. Nruam tej yam load tau nyob rau hauv mus ib txhis deformation ntawm lwm yam kev haum thiab mounting chaw ntawm lub dov zeb, lub caij no, nws yog ntxiv qub vim xeb ntawm cov khoom, uas tau nyob rau hauv tsis muaj tseeb tso ntawm cov ua hauj lwm yob thiab tus thaub qab yob thiab ntau zog ntawm tus yob kev coj tus kheej chock nyob rau hauv lub dov zeb muag zaub, ua rau nws tsis yooj yim rau zoo tswj lub clearance ntawm tus ntxuag zeb tsev nyob ncej thiab cov yob kev coj tus kheej chock.

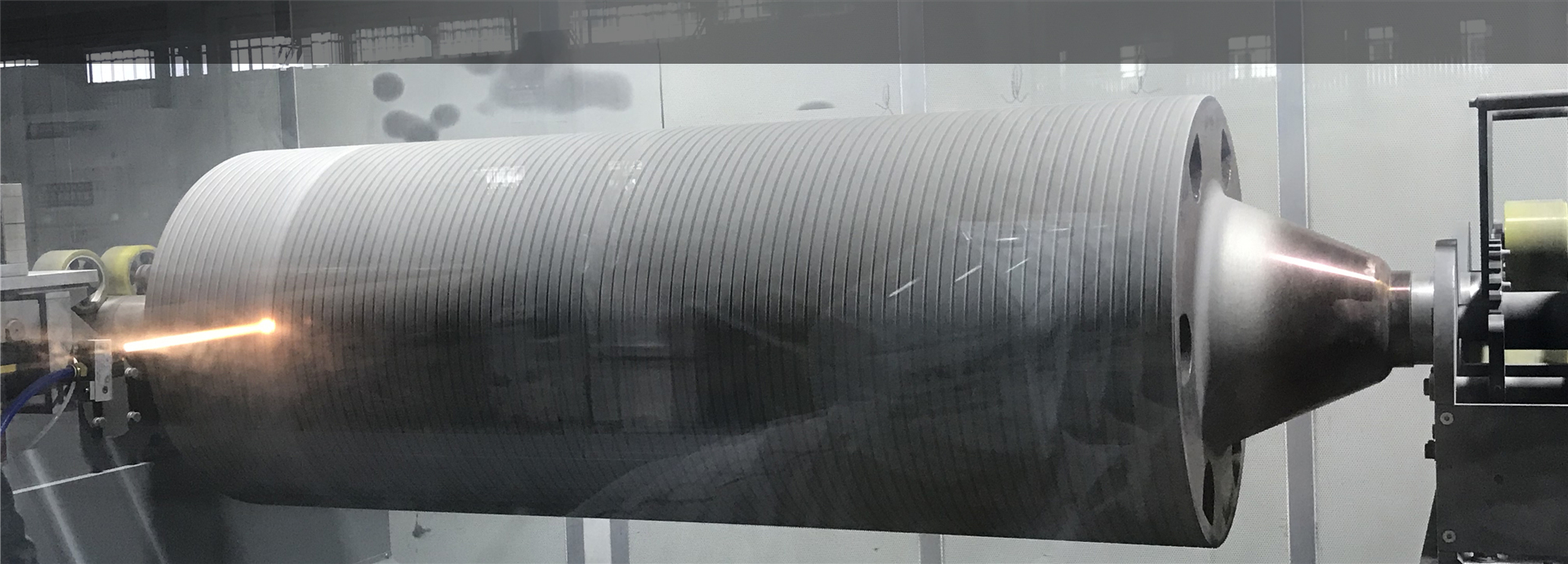

Peb nqa tawm on-site kho thiab remanufacturing ntawm lub dov zeb tsev nyob ncej los ntawm kev siv lub laser xab thiab nrhiav cov khoom, tshwj xeeb mobile machining cov khoom rau on-site kho thiab mobile laser cladding cov khoom, uas muaj qhov zoo siab kho precision, zoo coj kuj thiab corrosion kuj ntawm lub cladding txheej, zoo heev flatness thiab du finish ntawm qhov chaw hu, yog li ntawd, cov kev pab cuam lub neej ntawm tus ntxuag zeb tsev nyob ncej yog ho paub, tus ntxuag precision yog guaranteed thiab cov khoom zoo yog zoo.

Zoo heev ua yeeb yam:

High seem raug after repair of the rolling mill housing frame

Nrog rau cov me nyuam los tu ntawm on-site roughing ntawm lub tshuab cuab tam, laser cladding los ntawm lub tshuab cuab tam es tsis txhob ntawm lub ntxias thiab on-site finishing ntawm lub tshuab cuab tam tom qab laser cladding, nws lov cov tsoos kho txoj kev tshem cov tshuab cuab tam tom qab on- qhov chaw roughing, txhim kho lub ntxias rau laser cladding, tshem lub ntxias thiab nqa tawm los ntawm txhais tes polishing tom qab laser cladding. Tom qab kho, cov neeg kawm ntawv ntawm finish, seem raug thiab geometric siab tev taus ntawm lub dov zeb tsev nyob thiab yuav tsum tau 100% rov qab los mus rau tus thawj tsim uas yuav tsum tau.

Rau yav tom ntej cladding performance of the rolling mill housing frame

Peb lub tuam txhab tau tsim ib tug tshwj xeeb hmoov rau arches uas muaj anti-xeb, muaj zog coj kuj thiab hardness. Nws daws tau qhov teeb meem ntawm siab noj thiab tiv thaiv cov cracking nyob rau hauv lub hardening txheej vim ho txhim kho ntawm cov hardness gradient. Los ntawm re-raug thiab kho, cov nuj nqi ntawm cov khoom muaj peev xwm yuav zoo dua. Txhua xyoo puas poob ntawm qhov chaw yog ≦ 0.05 hli / xyoo thiab cov kev pab cuam lub neej yog ≥10 xyoo.

Tag nrho lub neej-cycle kev tswj cov dov zeb tsev nyob ncej

Peb tau tsim ib tug tag nrho lub neej-cycle txoj kev npaj tswj ntawm tus ntxuag zeb tsev nyob ncej xws li kev soj ntsuam, mob, kws muaj txuj pab neeg sib tham, kev ntsuam xyuas, kev daws teeb meem, modeling thiab simulation lag luam, online siv, ua raws li-up raws li txoj cai txij nkawm. Cov khoom yuav tsum kho nyob rau hauv ib tug high-zoo thiab high-npaum yam raws li nyob rau hauv ib tug ncauj lus kom ntxaws network ua hauj lwm txoj kev npaj.

Laser Remanufacturing ntawm Drive Ncej, tshaj Phaj ...

Laser Remanufacturing ntawm Drive Ncej, tshaj Phaj Thiab Lwm yam khoom Series

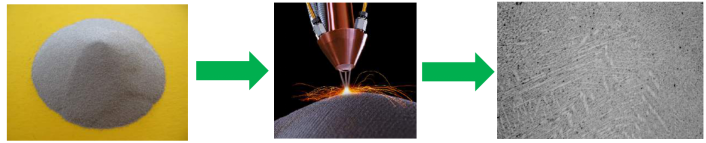

Laser additive remanufacturing technology (laser deposition raug LMD technology) no yog los tso ib tug nyias txheej ntawm cov hlau nyob hauv lub hauv paus cov ntaub ntawv uas los ntawm laser thaum tshav kub kub qhov chaw. Nws muaj qhov zoo ntawm cov uas tsis muaj tshav kub tswv yim ntawm substrate, me me kub feem, siab txias nqi, me me grain loj, metallurgical tsevneeg, siab tsevneeg lub zog, thiab lwm yam

Introduction ntawm laser cladding khoom ntawm Taier

Tshaj cushion phaj: lub tshaj cushion ntaus ntawv rau kub tas mus li dov yog ntsia tau rau hauv lub qaum kev ib lub rov qab-up yob chock thiab cov AGC lub tog raj kheej mus cuag yob kis nyuaj haum ntawm lub dov zeb thiab phaj thickness tswj thiab pab kom txawm peem rau variations nyob rau hauv txoj kab uas hla sib txawv ntawm cov yob. Peb tau txais laser cladding technology lug txhim khu cov tshaj cushion phaj nto remanufacturing, nyob rau hauv no txoj kev, lub coj kuj thiab corrosion kuj yog ho paub, thiab cov kev pab cuam lub neej yog nce los ntawm ntau tshaj li 5 lub sij hawm piv nrog rau cov pa quenching.

Drive ncej: tus tsav ncej rau steel dov ntau lawm kab no mas muaj li ntawm nruab nrab txuas ncej, sib koom tes, tiaj taub hau lub tes tsho thiab lwm yam tseem ceeb Cheebtsam; nyob rau hauv lub chaw ua haujlwm ntawm kub, siab cov av noo thiab siab zog, hais txog qhov chaw tej zaum yuav tiag corroded, hnav thiab puas. Peb txais yuav laser cladding technology rau kev laser cladding remanufacturing kho tseem ceeb Cheebtsam ntawm tus tsav ncej thiab qhov cuab lub zog ntawm cov khoom tshiab, thiab cov stability thiab kev pab cuam lub neej ntawm cov khoom yog paub heev.

Duab ntawm laser remanufacturing khoom