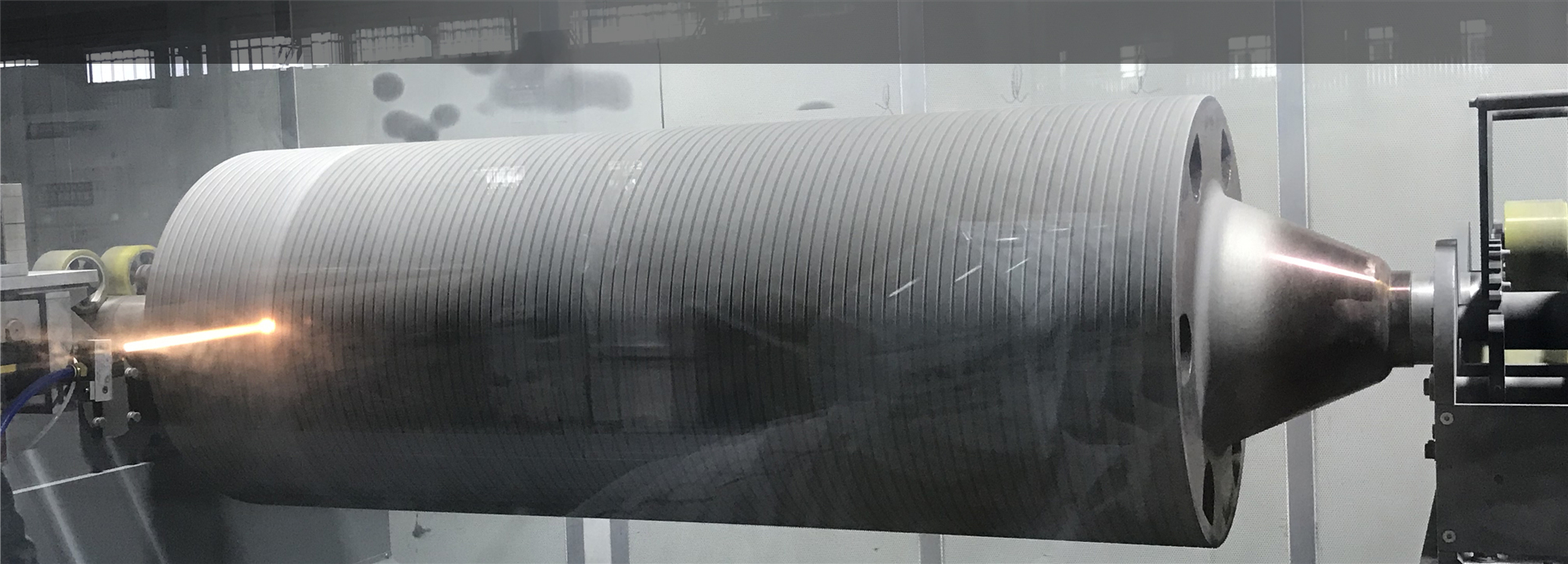

Rolling Mill Housing Frame - Laser Cladding Remanufacturing

Rolling Mill Housing Frame - Laser Cladding Remanufacturing

Phethola leloala matlo foreime o boetse o bitsoa phikolosetsa leloala koteleme, e leng e sebelisoa ho kenya rolara, rolara behang, rolara phetoho sesebediswa, tataisa thepa, joalo-joalo 'me e boetse ke ea bohlokoa mojaro-nkile karolo ea thepa sarolohang. E hangata ile a etsa ea castings tlwaelehileng tšepe le ho betsa thulaganyou e lona rerang hore holim 'mele ha a na matla a phahameng, ho hanyetsa ts'enyeho le tshebetso tse ling. Tsoelang pele diphetho tshusumetso mojaro ka deformation sa feleng e amana le loketseng le ntseng bo eketseha bokaholimo ba leloala phikolosetsa, Ka nako e tšoanang, ho e ka ho eketsehileng bo ntse bo mpefala ka lebaka la ho ts'enyeho ea lintho tse bonahalang tse, e leng se fellang ka ho sa nepahalang boemo ba moqolo sebetsa le moqolo bekapo le mokhatlo oa ka tsela e feteletseng ea moqolo le ho jara chock ka phethola leloala koteleme, ho etsa ho le thata ho ka tsela e atlehang laola rengwa pakeng tsa phikolosetsa foreime leloala matlo le moqolo le behe chock.

Re phetha ka-saeteng ho lokisa le remanufacturing tsa phethola leloala foreime matlo ka ho sebelisa mong bang laser ho lekanya le Tracking thepa, khethehileng selefouno machining thepa bakeng sa ka-saeteng ho lokisa le selefouno tham mong bang laser cladding thepa, eo na le melemo ea phahameng oa ho lokisa sebetsa ka ho nepahetseng, ba roale ntle ho hanyetsa le ho hanyetsa ts'enyeho ea cladding kolohantsoeng, flatness babatsehang le boreleli fihlela qetellong ea holim'a metsi ikopanye le hona, le ka bophelo ba tšebeletso ea phikolosetsa foreime leloala matlo e haholo ba ntlafala, e sebetsa ka ho nepahetseng sarolohang e Guaranteed le boleng sehlahisoa e ntlafala.

Babatsehang liketso:

Phahameng tlhakore nepahala ha after repair of the rolling mill housing frame

Le ho nkeloa ka lapeng la ka-saeteng roughing ba sesebelisoa mochini, tham mong bang laser cladding ke mochine sesebelisoa sebakeng sa molecules le on-saeteng qete tsa mochine sesebelisoa mora tham mong bang laser cladding, ho pshatla ho lokisa mokhoa e tloaelehileng ea ho tlosa mochine sesebelisoa mora on- saeteng roughing, kenya e molecules bakeng sa tham mong bang laser cladding, ho tlosa molecules le phetha pukwanana bentsa mora tham mong bang laser cladding. Ka mor'a ho lokisa, tekanyo ea ho fihlela qetellong, tlhakore ho nepahala le tsa thutatekanyo mamello ea phethola leloala foreime matlo tla 100% khutlisetsoa ditlhoko pele moralo.

Babatsehang cladding performance of the rolling mill housing frame

khampani ya rona e se e pele e phofo e khethehileng bakeng sa arches le phahameng-ba khahlanong le ts'enyeho, matla qhoaele hanyetsa le thatafala. Ho rarolla ka bothata ba ho fepa khatello le thibela petsoha ka thatafatsa lera ka lebaka la ho haholo ntlafatso ya thatafala kretiente. Ka ho etsa thepa botjha le ho lokisa, ho sebetsa ha thepa ea ka hantle ntlafala. The abrasion ho lahleheloa ke selemo le selemo oa holimo ke ≦ ya 0.05 limilimithara / selemo le bophelo tšebeletso ke lilemo tse ≥10.

Tletseng bophelo-potoloho ea taolo ya phikolosetsa leloala foreime matlo

Re qapile tletseng bophelo-potoloho ea bookameli ba phikolosetsa leloala matlo foreime ho akarelletsa le liteko, phumano, setsebi sehlopha rerisana, review, ditharollo botekgeniki, modelling le ketsiso sebetsa, ho kenngwa tshebetsong online, latela-up boemo tokiso. sehlahisoa sa tla lokisoa ka boleng bo phahameng 'me ka mokhoa phahameng-e sebetsang hantle e thehiloeng e qaqileng na mwango ya marangrang a mosebetsi.

Laser Remanufacturing tsa Drive theko, kenella Plate ...

Laser Remanufacturing tsa Drive theko, kenella Plate And Other Product Series

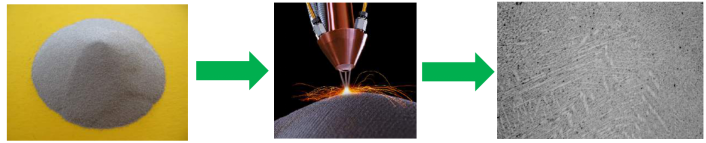

Laser tseloe remanufacturing thekenoloji (tham mong bang laser deposition etsa thepa thekenoloji LMD) ke ho beha mokato tšesaane ea tšepe ka lintho tse bonahalang e le setsi ka mong bang laser mocheso mohloli. Ho na le melemo ea tlaase mocheso input ea substrate, tse nyenyane tshusumetso mocheso, palo e phahameng tsidifatso, tse nyenyane boholo lijo-thollo, metallurgical oxyphobe, phahameng oxyphobe matla, joalo-joalo

Selelekela sa lihlahisoa tsa laser cladding tsa Taier

Kenella cushion poleiti: ho kenella cushion sesebediswa bakeng sa e chesang e tsoelang pele sarolohang e hlomamisa karolong e ka holimo ea moqolo chock morao-up le silindara AGC ho fihlela moqolo lekhalo karohano phetoho ya phethola leloala le poleiti botenya taolo le buseletsa bakeng sa mekete e fapaneng bophara le meqolong ea fapaneng. Re amohetse ka laser cladding thekenoloji ho ntlafatsa kenella cushion poleiti holim remanufacturing, ka tsela ena, ho apara liaparo tsa ho hanyetsa le ho hanyetsa ts'enyeho ba haholo ba ntlafala, 'me bophelo ba tšebeletso e ile ea eketseha ka makhetlo a fetang 5 bapisoa le tima tloaelehileng.

Drive theko: ho drive theko bakeng sa tšepe phethola tlhahiso ea mola e haholo-holo a qapa ea bohareng tlohang theko, e kopanetsoeng, e bataletse hlooho sleeve le dikarolo tse ding senotlolo; tlas'a tikoloho ho sebetsa tsa mocheso phahameng, mongobo le phahameng le matla a phahameng, likarolo amanang le ka ho teba corroded, tsofetseng le senyehile. Re amohela ka laser cladding thekenoloji ho khanna ka laser cladding remanufacturing ho lokisa ea likarolo senotlolo sa theko drive le matlafatso ea lihlahisoa tse ncha, 'me le botsitso le tšebeletso ea bophelo ea lihlahisoa li ntlafetse haholo.

Litšoantšo tsa lihlahisoa tsa laser remanufacturing