Oyi-akpọrepu Hot-mikpuo galvanized aro uwe Ma Bush

Oyi-akpọrepu Hot-mikpuo galvanized aro uwe Ma Bush

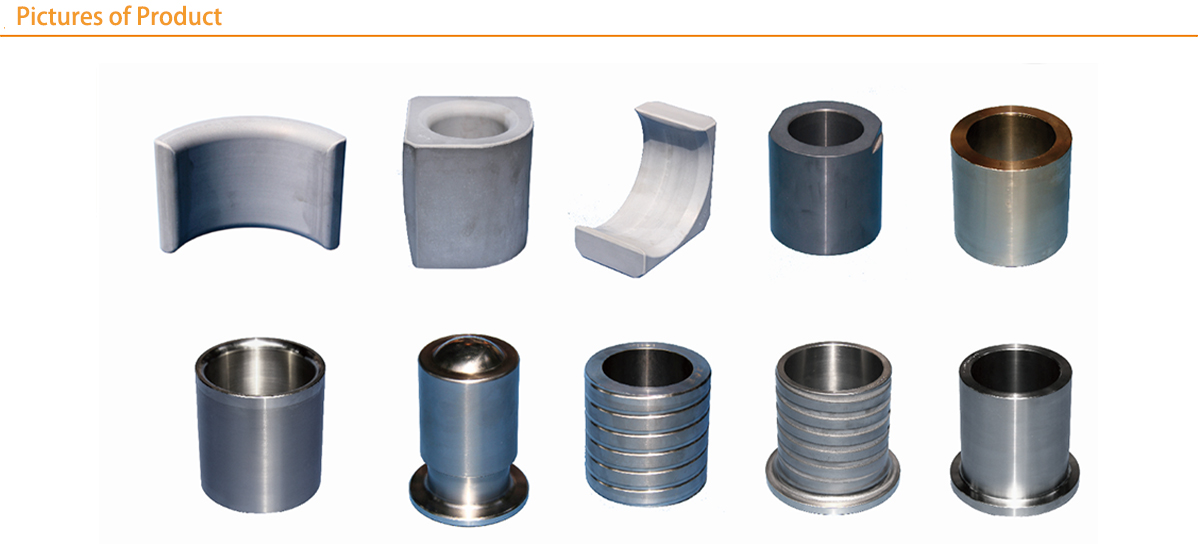

The aka uwe na bushing, bụ isi akụkụ maka a oyi Rolling ọkụ galvanization akara, na-arụnyere na ndị isi ya na ogwe aka a na-asa mpịakọta na kwụsie ike mpịakọta na-eji na-eje ozi dị ka mbanye biarin ndị a na-apụta. Ha ga-anabata ihe ịma aka site elu okpomọkụ, corrosion site wụrụ awụ zinc na abrasion. N'ihi nke a, omenala ngwaahịa nwere ọghọm nke a obere ọrụ ndụ, ogbenye kwụsie ike na elu mbara na-eri. Na elu ihe na pụrụ iche na usoro, anyị enwela uwe na bushing usoro na a sara mbara elu ugwu nke uru dị ka ndị na-eguzogide megide elu okpomọkụ, na-eguzogide megide abrasion na ike ọrụ. Ha nwere ike n'ụzọ dị irè aka ahịa mma ngwaahịa mma ma belata mbara na-eri ihe, si otú na-eju afọ ahịa choro maka dị iche iche na emeputa edoghi.

|

List of Series Products of Mkpa aka uwe na Bush nke Taier |

||||

|

Product Number |

ekweghị ekwe egwuregwu uwe-bushing |

Njirimara |

Target ahịa |

Product atụmatụ |

|

TAIER01 |

HRC60- seramiiki |

Okporo uwe: ★★★★★ Bushing: ★★★★★ |

Premium ụgbọ ala panel, home ngwa oru efere edoghi | Good kwụsie ike, Long ọrụ ndụ, High eri arụmọrụ, na-eduga mba |

|

TAIER02 |

HRC60-HRC45 |

Okporo uwe: ★★★ Bushing: ★★★★ |

Na-ajụ-elu-ọgwụgwụ ụgbọ ala ogwe, home ngwa oru efere edoghi | Good kwụsie ike, High eri arụmọrụ, The anụ ụlọ na-eduga |

|

TAIER03 |

HRC45- seramiiki |

Okporo uwe: ★★★★★ Bushing: ★★★ |

Na-ajụ-elu-ọgwụgwụ ụgbọ ala ogwe, home ngwa oru efere edoghi | Good kwụsie ike, High eri arụmọrụ, Dochie dị |

|

TAIER04 |

HRC40-HRC45 |

Okporo uwe: ★★★ Bushing: ★★★ |

nkịtị ụgbọ ala panel, home ngwa oru efere edoghi | Agafeghị oke price na pụtara ìhè arụmọrụ |

|

TAIER05 |

HRC30-HRC35 |

Okporo uwe: ★ Bushing: ★ |

Building efere akara (erughị ala nke zinc ite <500 n'arọ) | Low price |

Asa Roll Na-eguzosi Roll Series

Asa Roll Na-eguzosi Roll Series

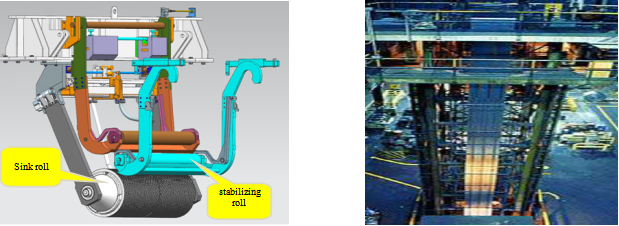

Zinc ite bụ isi bụ ngwá ọrụ nke oyi-Rolling na-aga n'ihu na-ekpo ọkụ-itinye galvanizing unit, n'etiti ha, ndị "atọ na-apụta" (sink mpịakọta, kwụsie ike mpịakọta na ndu mpịakọta) bụ isi mejupụtara ya na zinc ite. The "atọ na-apụta" na-amụkwu wụrụ awụ zinc ngwọta maka a ogologo oge, na iche iche iche iche nke zinc slags dị ka Zn-Fe, Fe-Al na Fe-Zn-Al bụ apụghị izere ezere na ugbu ke zinc mmiri mmiri, ya mere, n'elu àgwà nke "atọ na-apụta" ga na-emetụta àgwà na mkpụrụ nke warara ígwè, nke bụ eziokwu karịsịa na mmepụta nke n'elu-ọkwa ụgbọala elu mpempe akwụkwọ. The sink mpịakọta na kwụsie ike mpịakọta arụpụtara site Anhui Taier Mkpa Engineering Technology Co., Ltd. e ji elu na-eri arụmọrụ, ogologo ọrụ ndụ, wdg The n'elu seramiiki coatings nke sink mpịakọta, kwụsie ike mpịakọta na ndu mpịakọta mere na mba elu elu -velocity oxygen-manu (HVOF) technology na-agba na-elu wear-eguzogide ma na ike iguzogide zinc mmiri mmiri corrosion; mgbochi adhesion arụmọrụ nke mpịakọta elu na-enwekwukwa site na ọgwụgwọ nke pụrụ iche na-mepụtara n'elu akara Usoro; ugbu a, na kachasị imewe na Ụgha nke sink mpịakọta elu uzo na akara nke kwụsie ike mpịakọta n'elu microstructure, na slag orùrù arụmọrụ na iguzogide viscous slag na-ukwuu mma. Na upgrading nke onye ọrụ na ngwaahịa na-aga n'ihu mma nke warara quality chọrọ, ndị ọkachamara na ọgaranya ahụmahụ nke Anhui Taier Mkpa Engineering Technology Co., Ltd. ga-enye gị ahaziri ọrụ na usoro ngwọta na akụkụ nile na ike uru maka ịga nke ọma gị dabeere na ọnọdụ nke ndị ahịa set.

| Service ọnọdụ: |

Zn-Al mmiri mmiri / 460 ± 5 ℃, ọsọ ≤200m / min |

Mkpuchi usoro: |

HVOF / akara |

| Odida mode: | Corrosion, eyi, ekpepụsị |

Mkpuchi ihe onwunwe: |

dara seramiiki |

| Performance chọrọ: | Iguzogide wụrụ awụ zinc ngwọta corrosion, eyi ndị na-eguzogide, elu bonding ike | Service ndụ egosi: |

Life of mkpuchi: 40-60 ụbọchị |

Oku Roll Series

Oku Roll Series

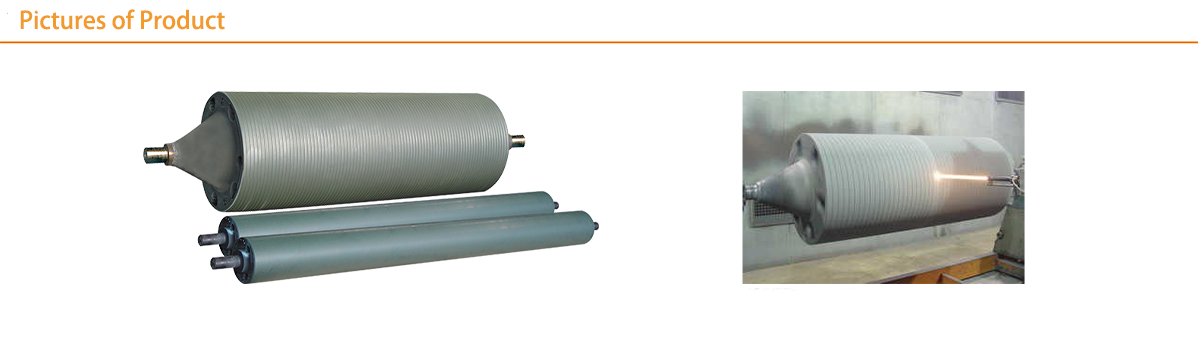

Ọkụ mpịakọta bụ a isi akụrụngwa na oyi na-atụ Rolling na-aga n'ihu annealing unit na-aga n'ihu na-ekpo ọkụ-itinye galvanizing unit annealing ọkụ. N'ihi ogologo oge ọrụ na elu okpomọkụ, na mgbakwunye na-enwe magburu onwe okpomọkụ eguzogide arụmọrụ gụnyere elu ike, ike iguzogide elu okpomọkụ ọxịdashọn corrosion, ezi wear-eguzogide ma na ndị magburu onwe thermal ujo eguzogide, oké ọku mpịakọta n'elu mkpuchi ga nwere magburu onwe ike iguzogide akwakọba burl (akwakọba burl nke Fe maka nkịtị nchara na-akwakọba burl nke igwe n'ihi na elu-ike ígwè) iji hụ na àgwà nke warara ígwè, ogologo oge roughness njigide arụmọrụ na oruru nke erughị ala na ọkụ. Anhui Taier Mkpa Engineering Technology Co., Ltd. adopts mba elu na-aga n'ihu spraying technology tinyere HVOF na plasma aak, akwa okpomọkụ superalloy + seramiiki mkpuchi arụpụtara nwere uru nke ogologo ọrụ ndụ na elu na-eri arụmọrụ, na elu post ọgwụgwọ na ngwá na technology nwere ike -eji na-Nlụpụta ọkụ na-apụta dị iche iche mpịakọta na ụdị na dị iche iche roughness.

| Service ọnọdụ: |

Okpomọkụ ≤1,100 ℃, N 2 + H 2 |

Mkpuchi usoro: |

APS, HVOF / akara |

|

Ụdị nke ịka nká: |

Scaffolding, abrasion, ịgbawa na corrosion |

Mkpuchi ihe onwunwe: |

NiCr-CRC, MCrAlY + Al 2O 3, MCrAlY + ZrB 2 |

|

Property chọrọ: |

Eguzogide ọgwụ elu okpomọkụ akpụ, abrasion na okpomọkụ ujo |

Service Life egosi: |

≥3 afọ |

Usoro Roll Series

Usoro Roll Series

The usoro mpịakọta na ọtụtụ-eji niile oyi Rolling nkeji na n'ozuzu na-arụ ọrụ na ikuku gburugburu ebe obibi, tumadi gụnyere: mbịne mpịakọta, mgbazi mpịakọta, erughị ala mpịakọta, erughị ala mita mpịakọta, loop azụ mpịakọta, wdg, na ọ na-bụ-eji maka nnyefe, mgbazi na ahụ erughị ukpụhọde nke warara, ya mere, ọ na-achọrọ na mpịakọta n'elu ga-enwe ezi wear-eguzogide ma na-erughị ala njigide arụmọrụ, wdg mpịakọta n'elu bụ kpọmkwem na kọntaktị na warara, ya mere, na mkpuchi n'elu Njirimara ga na-emetụta àgwà nke warara. Iji gboo mkpa nke usoro mpịakọta elu nke dị iche iche oyi Rolling nkeji na ọnọdụ dị iche iche, Anhui Taier n'elu Engineering Technology Co., Ltd. adopts merela agadi HVOF na post-omume technology nke mkpuchi iji nweta ndị e ji mara site na mirror n'elu na usoro mpịakọta elu na elu roughness. Advanced technology ana achi achi na ala nwere magburu onwe wear-eguzogide ma na roughness njigide arụmọrụ, na n'ụzọ kwesịrị ekwesị doziri nsogbu nke adhesion nke ndị mba ọzọ okwu na mpịakọta n'elu, si otú nzute onye ọrụ a chọrọ maka elu na-eri arụmọrụ, ogologo ọrụ ndụ, elu arụmọrụ na elu àgwà nke usoro mpịakọta.

| Service ọnọdụ: |

Atmosphere / mgbe nile okpomọkụ / HSS ọkụ galvanization akara |

Mkpuchi usoro: |

HVOF, machie + HVOF / quenching + HVOF |

| Odida mode: | Eyi, ekpepụsị, ndị mba ọzọ okwu adhesion |

Mkpuchi ihe onwunwe: |

Dara seramiiki / alloy ígwè + dara seramiiki |

| Performance chọrọ: | Eyi-eguzogide, elu bonding ike, iguzogide ndị mba ọzọ okwu zọpịa |

Life egosi: |

Mma site karịa ugboro 3 tụnyere Gr galvanized mpịakọta |

Side Guide nke Hot Rolling Production Line

Side Guide nke Hot Rolling Production Line

The n'akụkụ ndu a na-akpọ ndu, nke bụ akụkụ dị mkpa nke na-ekpo ọkụ Rolling mmepụta akara na a na-eji hụ na nkwụsi ike na directionality nke ọkụ-akpọrepu warara n'oge njem (karịsịa tupu coiling), n'ozuzu, e nwere otu ìgwè ma ọ bụ ọtụtụ iche iche nke n'akụkụ nduzi. N'oge ọrụ nke na-ekpo ọkụ Rolling unit, na elu-okpomọkụ na elu-ọsọ na-ekpo ọkụ-akpọrepu mpempe akwụkwọ na kọntaktị na rubs na akuku ndu, nke utịp ke ndị dị oké njọ na-eyi nke na kọntaktị akụkụ na-eme ka ndị dị otú ahụ mma nsogbu dị ka burrs na ọkọ na nsọtụ nke na-ekpo ọkụ-akpọrepu mpempe akwụkwọ. The wear ọnwụ nke akuku ndu mere nke ot carbon ígwè bụ 10-15mm a ụbọchị, nke utịp ke nnọchi na ndozi nke n'akụkụ ndu nke na-ekpo ọkụ Rolling unit kwa ụbọchị.

The amorphous mejupụtara seramiiki mkpuchi chepụtara site anyị ụlọ ọrụ na elu plasma cladding technology nwere magburu onwe nkịtị okpomọkụ ekweghị ekwe na elu okpomọkụ ekweghị ekwe, ugbu a, na kachasị chemical mejupụtara nke ihe onwunwe, na esemokwu ọnụọgụ n'ụzọ dị irè belata na wear-eguzogide ihe onwunwe nke ihe onwunwe bụ ukwuu mma. The ngwaahịa e ji anụ ụlọ-eduga na mba na-elu technology, na n'akụkụ ndu arụpụtara nwere a ọrụ ndụ nke ruo 5-7 ụbọchị.

Magburu onwe-eri arụmọrụ

- Belata ibu na mmepụta saịtị

Nnọchi mere otu ugboro n'ụbọchị na-akakwa mma ka ozugbo ọ bụla 5-7 ụbọchị, na-arụ maka nnọchi nke mmezi anya na-ebelata na idozi ịgbado ọkụ na-tutu amama; na saịtị na-tọhapụrụ na ego nke akụkụ ahụ mapụtara maka akụkụ ndu na-ebelata.

- Mbenata wear ma rụọ ọrụ ngwaahịa mma

The uzo omimi nke ogologo-ndụ n'akụkụ ndu mbelata mgbe eyi, mbenata mmebi nke na-ekpo ọkụ Rolling warara ma melite ogo nke na-ekpo ọkụ Rolling warara product.The yi omimi nke carbon ígwè n'akụkụ ndu karịa 5 mm kwa ụbọchị, na ike eru ọbụna 10-15 mm.The ngụkọta yi omimi nke n'akụkụ nduzi nakweere na nkà na ụzụ ọhụrụ nwere ike na-ebelata ka 1 mm kwa ụbọchị.

- Meziwanye mmepụta nke na-ekpo ọkụ Rolling mmepụta akara

Mbelata nnọchi ugboro bụ uru na-abawanye nke ubi mmepụta. Ọ bụrụ na ndị ọrụ ndụ nke n'akụkụ ndu ụba si 1 ụbọchị 5 ụbọchị, mmepụta oge nke na-ekpo ọkụ Rolling mmepụta akara nwere ike mụbara site 8 awa kwa ọnwa. Ewere 1780 ọkụ Rolling mmepụta akara dị ka ihe atụ, ọ dịkarịa ala 1,000 tọn ọkụ-akpọrepu Ibé akwụkwọ nwere ike ụba kwa afọ.

O Belata ibu na mmepụta saịtị

Laminar Jụrụ Roll

Laminar Jụrụ Roll

Laminar obi jụrụ mpịakọta arụnyere n'etiti finishing na nkume igwe nri na recoiler nke na-eji na-ekpo ọkụ warara Rolling na nkume igwe nri. The okpomọkụ nke warara na-tightly achịkwa mmiri jụrụ iji hụ na nkịtị ọrụ nke coiling. The laminar obi jụrụ mpịakọta na tumadi kewara n'ime jụrụ mpịakọta na elu jụrụ mpịakọta. Mgbe ọkụ Rolling na nkume igwe nri bụ na-arụ ọrụ, esemokwu n'etiti ọkụ Rolling warara na elu okpomọkụ ma na elu na-agba na mpịakọta, na obi jụrụ mpịakọta elu na-doro ugboro ugboro ozize na jụrụ nke ekesa mmiri. Isi odida ụdị ot laminar jụrụ mpịakọta ndị wear nke mpịakọta elu, corrosion, mpịakọta n'elu ekpepụsị, na ala mbanye yinye ọdịda.

The elu-arụmọrụ laminar jụrụ mpịakọta mepụtara anyị ụlọ ọrụ adopts elu laser cladding technology. Mpịakọta n'elu nwere magburu onwe wear-eguzogide ma na corrosion eguzogide. The obi tara mmiri oyi akwa na mpịakọta ahụ na-Metallurgical bonding na elu bonding ike. N'otu oge, site na optimizing na rụọ ihe na Ọdịdị na ike nke obi jụrụ mpịakọta na-ọma ka mma, onu nke mmiri ingress na jamming nke amị na-irè gbochie, na ọrụ ndụ na imepụtaghachi ugboro na-akakwa mma. The ngwaahịa technology esịmde eduga ọnọdụ ma n'ụlọ na mba ọzọ. The ọrụ ndụ nke laminar obi jụrụ mpịakọta n'elu bụ ugboro abụọ na nke mpịakọta n'ịkpa ịgba ịgbado ọkụ usoro.

Magburu onwe-eri arụmọrụ:

Magburu onwe tara mmiri oyi akwa arụmọrụ

Site tinye n'ọrụ laser cladding technology ji ngwa kwes na ngwa ngwa jụrụ, na-arụ ọrụ usoro nke preheating na annealing na-tutu amama. The okpomọkụ nke mkpụrụ a na-lowered ka belata okpomọkụ na-emetụta nke na-arụ ọrụ ibe. The cladding oyi akwa na mkpụrụ bụ ukwuu Metallurgical bonding. The cladding oyi akwa a finely haziri enweghị ezi pores, na ya nwere magburu onwe wear-eguzogide ma na corrosion eguzogide.

Kwụsie & pụrụ ịdabere

Mpịakọta ahụ na spindle isi na-mere nke elu ike ihe. Ịghasa ọnwụ, ájá ọgbụgba ọkụ na remelting na-achọrọ na nkwadebe usoro nke mkpuchi, nke budata mma were osisi ike. nke obi jụrụ mpịakọta. Site njikarịcha na mma nke na-amị akara Ọdịdị, phenomena nke agba mmiri ingress na jamming na-irè gbochie.

Ogo nke warara ígwè bụ mma na gburugburu ebe obibi mmetọ na-ebelata

The ọrụ ndụ nke ala n'onwe ya na-akp n'ihi na nke kacha mma na-eyi ndị na-eguzogide na corrosion na-eguzogide, nke mma mma n'elu quality nke warara ígwè ngwaahịa. Mmepụta usoro nke anyị ụlọ ọrụ elu-arụmọrụ laminar jụrụ mpịakọta nwere ala oriri ike na-ezukọ na chọrọ nke green n'ichepụta enweghị gburugburu ebe obibi mmetọ.

Crystallizer maka n'ihu Nkedo

Crystallizer maka n'ihu Nkedo

The crystallizer na-aga n'ihu mgbatị unit bụ a enweghi ike ígwè ingot ebu nke amanye mmiri jụrụ, nke a na-emekarị na-akpọ "obi" nke na-aga n'ihu mgbatị ngwá na na-bụ-eji na-eme ka a wụrụ awụ ígwè nwayọọ nwayọọ sikwuo ike n'ime slab shei nke chọrọ size na udi ma hụ na edo, anụ na-aga n'ihu na ọgbọ nke slab shei. Crystallizer ọla kọpa efere bụ isi akụrụngwa na a "obi", elu nke ọla kọpa efere bụ kpọmkwem na kọntaktị na wụrụ awụ ígwè, na esemokwu na elu nke ọla kọpa efere na-esiwanyekwa ike mgbe ahụ a wụrụ awụ ígwè na-sikwuo ike n'ime slab shei, gbakwunyere na corrosion site echebe slag, ya mere, ọla kọpa efere n'elu ga-ọma iguzogide thermal cracking, eyi na corrosion. The crystallizer ọla kọpa efere arụpụtara site Anhui Taier n'elu Engineering Technology Co., Ltd. bụ a mkpuchi eguzogide elu okpomọkụ, eyi na corrosion na-mere na elu HVOF, na isi mmiri bụ nnukwu okpomọkụ alloys ma ọ bụ elu okpomọkụ alloys + ceramik na ndị ọzọ ihe. The magburu onwe Njirimara nke mkpuchi ihe hụ na ọla kọpa efere nwere ike na-arụ ọrụ na elu ịbịaru ọsọ na ngụkọta ego nke ígwè mee na otu oge na-budata mma, na-ebelata n'ozuzu-eri n'ihi na ọrụ nke onye ọrụ na ngwá na ihe-ọmume nke unit mmepụta.

| Service ọnọdụ: | Okpomọkụ nke kọntaktị n'elu na mmiri mmiri ígwè ≤500 ℃ | Mkpuchi usoro: | HVOF / Remelting |

| Odida mode: | Eyi, mgbape, corrosion | Mkpuchi ihe onwunwe: | Eyi-eguzogide alloy |

| Performance chọrọ: | Eyi-eguzogide, corrosion eguzogide, ezi kwes conductivity | Life egosi: | Mma site 4-6 ugboro tụnyere electro-kpaliri Ni |