Batang-phuthoa Hot-ina Galvanized theko Sleeve And Bush

Batang-phuthoa Hot-ina Galvanized theko Sleeve And Bush

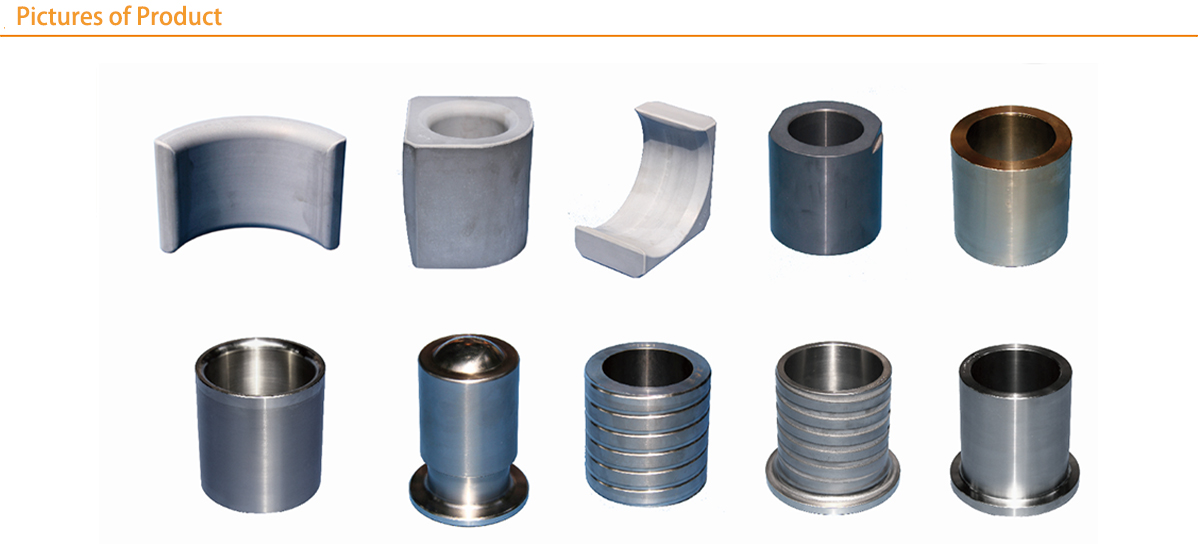

The sleeve le bushing, ke likarolo senotlolo bakeng sa batang phikolosetsa mola chesang galvanization, ba hlomamisa e le lihlooho 'me matsoho a teba moqolo le moqolo botsitso' me a sebelisa ho sebeletsa e le dibering le ka koloi ea meqolong tsena. Ba lokela ho mamella le bothata ho tloha mocheso le phahameng, ts'enyeho ke zinki entsoeng ka ho qhibilihisoa le abrasion. Ka lebaka lena, lihlahisoa tsa moetlo na le go tlhoka mesola ya bophelo lekgutshwanyane tšebeletso, botsitso mafutsana le phahameng theko akaretsang. Ka thepa e tsoetseng pele le thulaganyo khethehileng, re ntshetswa pele ea sleeve le bushing letoto la lihlooho tse nang le mefuta e fapaneng sephara ea menyetla joaloka ho hanyetsa khahlanong le mocheso phahameng, ho hanyetsa khahlanong le abrasion le tshebetso tsitsitseng. Ba ile ba ka katleho thusa bareki ntlafatsa boleng sehlahisoa le ho fokotsa litšenyehelo akaretsang, ka tsela eo e khotsofatsang ditletlebong moreki bakeng sa mela fapaneng tlhahiso.

|

List of Series Products tsa Bokaholimo Sleeve le Bush oa Taier |

||||

|

sehlahisoa Number |

thatafala papali sleeve-bushing |

litšobotsi tse |

maraka shebiloeng |

Product tšobotsi |

|

TAIER01 |

HRC60- ceramic |

Theko sleeve: ★★★★★ Bushing: ★★★★★ |

Premium koloi ka phanele, lapeng appliance poleiti mela | Good botsitso, Long bophelo tšebeletso, High theko tshebetso, Lebisang machaba |

|

TAIER02 |

HRC60-HRC45 |

Theko sleeve: ★★★ Bushing: ★★★★ |

Mahareng-ho diphanele koloi phahameng-qetellong, lapeng appliance poleiti mela | Good botsitso, High theko tshebetso, The bo lebisang malapeng |

|

TAIER03 |

HRC45- ceramic |

Theko sleeve: ★★★★★ Bushing: ★★★ |

Mahareng-ho diphanele koloi phahameng-qetellong, lapeng appliance poleiti mela | Good botsitso, High theko tshebetso, nka sebaka imported |

|

TAIER04 |

HRC40-HRC45 |

Theko sleeve: ★★★ Bushing: ★★★ |

ho tloaelehile hore batho koloi ka phanele, lapeng appliance poleiti mela | theko e leka-lekaneng le tshebetso e ikhethang |

|

TAIER05 |

HRC30-HRC35 |

Theko sleeve: ★ Bushing: ★ |

Building poleiti mola (tsitsipano ea pitsa zinki <500 Kg) | theko e tlase |

Teba Roll And botsitso Roll Series

Teba Roll And botsitso Roll Series

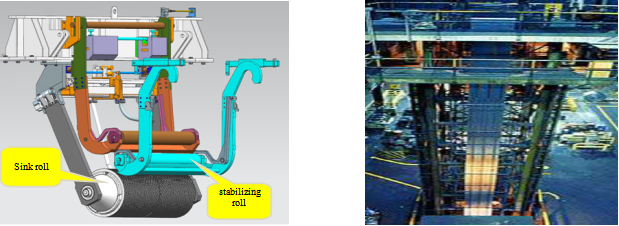

Zinki pitsa ke thepa senotlolo sa batang-roller e tsoelang pele e chesang-ina tlotsa metale ka senke yuniti, har'a bona, e leng "meqolong e meraro" (teba moqolo, botsitso moqolo le tataiso moqolo) ke dikarolo konokono ka pitsa zinki. The "meqolong e meraro" ba qoelisoa ka entsoeng ka ho qhibilihisoa zinki tharollo bakeng sa nako e telele, le mefuta e fapaneng ya slags zinki kang Zn-Fe, Fe-Al le Fe-Zn-Al ke hona joang kapa joang joale ka mokelikeli zinki hona, holim ' boleng ba "meqolong e meraro" e tla ka ho toba ama boleng le ka lihlahisoa tsa tšepe hlobolisa, e leng 'nete haholo-holo ka ho hlahisa ka holimo-sehlopheng koloi lakane ka ntle. The teba moqolo le botsitso moqolo etsoa ke Anhui Taier Bokaholimo Engineering Technology Co., Ltd. e tšoauoa ka phahameng theko tshebetso, bophelo tšebeletso e telele, joalo-joalo The bokaholimo ceramic coatings ea teba moqolo, botsitso moqolo le tataiso moqolo entseng le matjhabeng e tsoetseng pele phahameng -velocity oksijene-mafura a (HVOF) thekenoloji tse hlahang ka qhoaele hanyetsa phahameng le ho hanyetsa ka matla hore zinki ts'enyeho se metsi; tshebetso-ba khahlanong le mamarello ya holim'a metsi moqolo e ntlafatsoa ka ho phekola ka ho khethehileng-pele holim 'tiisoa ha ho mokhoa; Ho sa le joalo, ka ho rala tokafadiwa le popontshwa ea teba moqolo holim groove ka le taolo ya botsitso moqolo holim microstructure, ho slag tjhajoloha tshebetso le ho hanyetsa slag viscous li ntlafetse haholo. Le ntlafatso ea lihlahisoa tsa mosebedisi le ntlafatso e tsoelang pele ea ditlhoko hlobolisa quality, litsebi le boiphihlelo ke ba ruileng ba Anhui Taier Bokaholimo Engineering Technology Co., Ltd. tla u fa ditharollo namana tšebeletso le tsamaiso likarolong tsohle le bopa boleng bakeng sa katleho ea hao e thehiloeng ka maemo a oa sete moreki.

| boemo Tšebeletso: |

Zn-Al mokelikeli / 460 ± 5 ℃, lebelo ≤200m / mets |

Barbotage thulaganyo e: |

HVOF / tiisitsoe |

| Hloleha mokgwa wa: | Ts'enyeho, apara, gommage |

Barbotage lintho tse bonahalang: |

Metallic ceramic |

| ditlhoko Performance: | Ho hanyetsa entsoeng ka ho qhibilihisoa zinki tharollo ts'enyeho, apara ho hanyetsa, phahameng oxyphobe matla | Service bophelo pontshi: |

Life of barbotage: matsatsi a 40-60 |

Sebōpi Roll Series

Sebōpi Roll Series

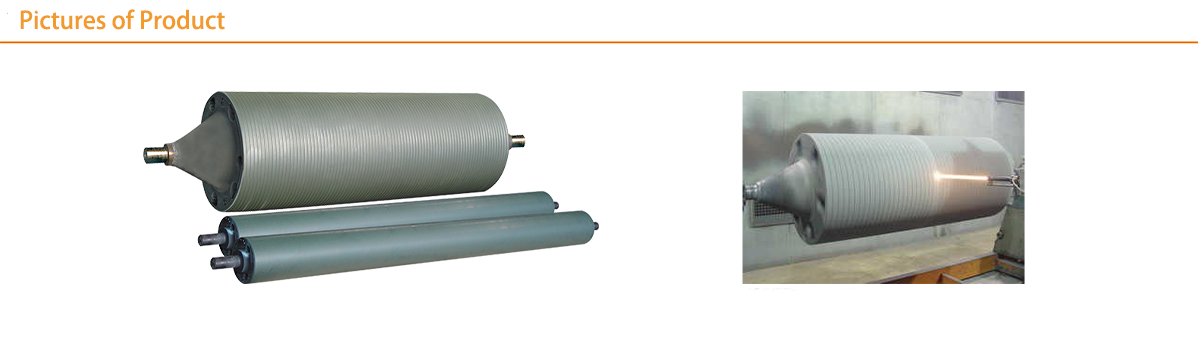

Sebōpi moqolo ke liboto motsoako ka batang sarolohang e tsoelang pele annealing unit trust mme e tsoelang pele e chesang-ina tlotsa metale ka senke unit trust annealing sebōpi. Ka lebaka la tšebeletso ea nako e telele ka mocheso phahameng, ho phaella ho ho ba le khabane ka ho fetisisa mocheso tshebetso manganga ho akarelletsa le matla a phahameng, ho hanyetsa le matla ho phahameng mocheso ho kena moea ts'enyeho, ntle ba roale hanyetsa le babatsehang ho hanyetsa mogote makala, ho barbotage sebōpi moqolo holim lokela ho ba le bokhoni bo babatsehang ho hanela bokeletseng Burl (bokeletseng Burl tsa Fe tsa tšepe ba tloaelehileng le bokeletseng Burl tsa MN bakeng phahameng-matla a tšepe) ho etsa bonnete ba boleng ba tšepe hlobolisa, nako e telele roughness tshegetsa le go tlotla tshebetso le ho thehoa ha tsitsipano sebōpi. Anhui Taier Bokaholimo Engineering Technology Co., Ltd. o inkela machaba e tsoetseng pele e tsoelang pele ho nyanyatsoa thekenoloji ho akarelletsa HVOF le lero la mali selikalikoe, e phahameng mocheso superalloy + ceramic barbotage etsoa na le menyetla ea ho phela nako e telele tšebeletso le tshebetso e phahameng theko, le e tsoetseng pele thepa poso kalafo le thekenoloji ka sebelisoa ho proizvodnje meqolong sebōpi tsa mefuta e sa tšoaneng moqolo le roughness fapaneng.

| boemo Tšebeletso: |

Mocheso ≤1,100 ℃, N 2 + H 2 |

Barbotage thulaganyo e: |

APS, HVOF / tiisitsoe |

|

Foromo ya botsofali: |

Sikarisa baithuti maikarabelo, abrasion, khoa le ts'enyeho |

Barbotage lintho tse bonahalang: |

NiCr-CrC, MCrAlY + Al 2O 3, MCrAlY + ZrB 2 |

|

Thepa e hlokahalang: |

Manganga ho phahameng mocheso hlahala, abrasion le mocheso makala |

Service Bophelo pontshi: |

lilemo tse ≥3 |

Process Roll Series

Process Roll Series

Tsela moqolo ho pharaletseng sebelisoa ka diyuniti tsohle batang phikolosetsa 'me ka kakaretso sebetsa ka tikoloho sepakapakeng, haholo-holo ho akarelletsa le: ho retelehela moqolo, khalemelo moqolo, tsitsipano moqolo, tsitsipano mitha moqolo, sekgoqetsane morao moqolo, joalo-joalo,' me e haholo-holo sebelisoa bakeng sa phetiso, khalemelo le tsitsipano phetoho ya hlobolisa, ka lebaka leo, ho hlokahala hore holim moqolo tla ba e ntle ba roale hanyetsa le tsitsipano tshegetsa le go tlotla tshebetso, joalo-joalo holim moqolo e ka ho toba le hlobolisa le hona, le ka thepa barbotage holim'a metsi e tla ka ho toba ama boleng ya hlobolisa le. Ho kopana le le litlhoko tsa bokaholimo thulaganyou e moqolo oa fapaneng diyuniti batang sarolohang le libaka tse sa tšoaneng, Anhui Taier holim Engineering Technology Co., Ltd. o inkela tsoetse pele HVOF le poso-kalafo theknoloji ea barbotage ho fumana litšobotsi tloha seiponeng holim ho holim thulaganyou e moqolo le phahameng roughness. theknoloji e tsoetseng pele ho etsa bonnete ba hore rolara o babatsehang qhoaele hanyetsa le roughness tshegetsa le go tlotla tshebetso, 'me hantle rarolla ka bothata ba mamarello ea taba tsoang linaheng tse ling ka holim'a metsi moqolo, ka tsela eo ho kopana ditlhoko le mosebedisi bakeng sa theko tshebetso e phahameng, bophelo bo bolelele tšebeletso, bokgoni phahameng le boleng bo phahameng la tshebetso moqolo.

| boemo Tšebeletso: |

Sepakapaka / mocheso kamehla / HSS chesang galvanization mola |

Barbotage thulaganyo e: |

HVOF, overlaying + HVOF / tima + HVOF |

| Hloleha mokgwa wa: | Apara, gommage, taba baditjhaba mamarello |

Barbotage lintho tse bonahalang: |

Metallic ceramic / motsoako tšepe + Metallic ceramic |

| ditlhoko Performance: | Apara ho hanyetsa, phahameng oxyphobe matla, ho hanyetsa sithabetsa taba tsoang linaheng tse ling |

Bophelo pontshi: |

Ntlafala ke ka makhetlo a fetang 3 bapisoa le Gr galvanized moqolo |

Lehlakoreng Guide of Hot Rolling Production Line

Lehlakoreng Guide of Hot Rolling Production Line

motataisi lehlakoreng o boetse o bitsoa tataiso, e leng karolo ea bohlokoa ea moleng chesang phikolosetsa tlhahiso le e sebelisoang ho etsa bonnete ba le botsitso le ditshupiso tsa chesang-phuthoa hlobolisa nakong tsamaea (haholo-holo pele coiling), ka kakaretso, ho na le sehlopha kapa tse ngata lihlopha tsa itsebisa lehlakoreng. Nakong ea tshebetso ya chesang phikolosetsa yuniti, ea phahameng-mocheso le tse phahameng-lebelo chesang-phikolosetsa lakane le mabitso rubs le tataiso lehlakoreng, e leng se ka ba qhoaele ka lintho tse tebileng tsa ho ikopanya le karolo le ho etsa hore mathata a joalo boleng ka burrs le mengoapo ka bohale le ya chesang-phikolosetsa lakane. The qhoaele tahlehelo ya lehlakoreng tataiso e entsoe ka tloaelehileng k'habone tšepe e 10-15mm letsatsi, e leng se ka Phetolo le ho lokisa tsa lehlakoreng tataiso ea unit trust e chesang phikolosetsa letsatsi le letsatsi.

The amorphous le likarolo tse ngata ceramic barbotage iqapetse ke khamphani ea rōna le tsoetseng pele e teng theknolojing lero la mali cladding o babatsehang ho tloaelehile mocheso thatafala le phahameng mocheso thatafala, Ka nako e tšoanang, ka optimized lik'hemik'hale tsa lintho tse bonahalang tse, coefficient le khohlano e ka katleho fokotswa le qhoaele-hanela thepa ya lintho tse bonahalang tse ke ntlafetse haholo. sehlahiswa e tšoauoa ka thekenoloji malapeng-e leng ho lebisang le machaba-e tsoetseng pele, 'me lehlakoreng le tataiso etsoa o na le bophelo tšebeletso ea matsatsi a ho fihlela ho 5-7.

tshebetso babatsehang theko

- Fokotsa workload setšeng sa tlhahiso

Phetolo entsoeng hang ka letsatsi e ntlafetse ho hang mong le e mong matsatsi a 5-7, e workload bakeng sa Phetolo ya basebetsi ho boloka e fokotsehile 'me ho lokisa tjheseletsa e felisoa; site e lokolloa 'me palo ya likarolo tse katileng maemo bakeng sa lehlakore le tataiso e fokotsehile.

- Fokotsa qhoaele le ho ntlafatsa boleng sehlahisoa

Hara groove botebo ba nako e telele-bophelo lehlakoreng tataiso decreases mora tsofaleng, fokotsa tšenyo ho chesang phikolosetsa hlobolisa le ho ntlafatsa boleng ba chesang phikolosetsa hlobolisa product.The apere botebo tsa carbon tšepe lehlakoreng tataiso e fetang 5 limilimithara ka letsatsi, 'me ka esita le fihle 10-15 mm.The palo yohle apere botebo ba itsebisa lehlakoreng e amohetsweng ka thekenoloji e ncha ka fokotswa ho ea ho 1 limilimithara ka letsatsi.

- Ntlafatsa khumo ea mola chesang phikolosetsa ho hlahisoeng

Phokotsong ea Phetolo maqhubu a na le molemo ho eketseha ha tlhahiso ea tšimo. Ha bophelo ba tšebeletso ea lehlakoreng tataiso e eketseha ho tloha ho letsatsi 1 ho matsatsi a 5, ho hlahisa ka nako ya mola chesang phikolosetsa tlhahiso ea ka ea eketseha ka lihora tse 8 khoeli le khoeli. Etellang 1780 chesang phikolosetsa tlhahiso ea mola e le mohlala, lithane tse bonyane 1,000 tsa maqephe a chesang-phuthoa ka e ile ea eketseha ka selemo.

O Fokotsa workload setšeng sa tlhahiso

Laminar Cooling Roll

Laminar Cooling Roll

Laminar Cooling moqolo e hlomamisa pakeng tsa qete leloala le recoiler eo e sebelisoa ka le chesang hlobolisa phikolosetsa leloala. Thempereichara hlobolisa e thata-thata e laoloa ke tsidifatso metsi ho netefatsa tshebetso tloaelehileng ea coiling ena. The laminar Cooling moqolo e haholo-holo arotsoe ka tsidifatso moqolo ka hare le tsa ka ntle tsidifatso moqolo. Ha chesang phikolosetsa leloala e sebetsa, khohlano pakeng tsa phikolosetsa hlobolisa hot mocheso phahameng le phahameng lebelo le moqolo, 'me ka Cooling holim moqolo e tlas'a khoholeho ea mobu a pheta le tsidifatso tsa metsi e potoloha. Ba ka sehloohong ho hloleha mefuta ea tloaelehileng laminar tsidifatso moqolo ke qhoaele ya holim'a metsi moqolo, ts'enyeho, moqolo holim gommage, le rolara drive ketane ho hloleha.

The phahameng tshebetso laminar tsidifatso moqolo ntshetswa pele ke khampani ya rona o inkela e tsoetseng pele ka laser cladding theknoloji. Holim moqolo o babatsehang qhoaele hanyetsa le ho hanyetsa ts'enyeho. Lera tiile lipelo le 'mele moqolo ke metallurgical oxyphobe le matla a phahameng oxyphobe. Ka nako e tšoanang, ke go lekanyetsa le ho ntlafatsa lintho tse bonahalang le sebopeho le matla a moqolo Cooling e hantle ntlafala, lipono tse makatsang tsa ingress ea metsi le jamming ea behang e ka katleho thibela, 'me bophelo bo sa tšebeletso le ho ikatisa makhetlo a ba boetse ba ntlafala. Theknoloji sehlahisoa fihla boemong ba itlhommeng pele ka bobeli lapeng le linaheng tse ling. Bophelo tšebeletso ea laminar Cooling moqolo holim'a ke ka makhetlo a mabeli hore ba tshebetso moqolo amohela spray tjheseletsa.

Babatsehang theko tshebetso:

Babatsehang tiile lipelo lera tshebetso

Ke ts'ebelisong ea tham mong bang laser cladding thekenoloji tšoauoa ka potlako mogote le ka potlako tsidifatso, ea ka mokhoa o sebetsa oa preheating le annealing li felisitsoe. Thempereichara substrate e theolela ho fokotsa mocheso ama ya mosebetsi-sengoathoana. The cladding lera le substrate ke haholo metallurgical oxyphobe. The cladding lera e khabeloa hlophisitse ntle pores e metle, 'me e na le e babatsehang qhoaele hanyetsa le ho hanyetsa ts'enyeho.

Botsitso & tšepahala

'Mele oa moqolo le hlooho leakage radiation ba entsoe ka lintho tse bonahalang e phahameng matla. Nsete ho itšeha, ho qhomisa lehlabathe le remelting ha hlokahala ka ho lokisetsa mokhoa oa ho barbotage, e leng haholo ntlafatsa tšebeliso matla. ba moqolo Cooling. Ka gogolo le ntlafatso ya sebopeho behang tiiso, le liketsahalo ea ho jara ingress ea metsi le jamming ba ka katleho thibela.

Boleng ba hlobolisa tšepe e ntafaditsweng le tšilafalo ea tikoloho e fokotsehile

bophelo tšebeletso ea rolara ka boeona e atoloswa ka lebaka la lona babatsehang qhoaele hanyetsa le ts'enyeho hanyetsa, eo molemo ho ntlafatsa boleng holim 'a sehlahisoa hlobolisa tšepe. Tsela tlhahiso ea khamphani phahameng tshebetso laminar tsidifatso rona moqolo o noang eneji, le tlaase 'me o kopana ditlhoko tsa tala difeme ntle tšilafalo ea tikoloho.

Crystallizer bakeng sa ho lahla e tsoelang pele

Crystallizer bakeng sa ho lahla e tsoelang pele

The crystallizer ka tsoelang pele ho betsa unit trust ke mohohlo tšepe ingot hlobo tsa qobelloa metsi tsidifatso, eo hangata e bitsoang "pelo" ea thepa e tsoelang pele ho betsa le ho e haholo-holo sebelisoa ho etsa hore tšepe e qhibilihisitsoeng butle-butle ile ea tiisa ka letlapa khetla ea hlokahala ka boholo le sebōpeho le ho netefatsa junifomo, moloko o mong tsitsitseng le e tsoelang pele ea khetla letlapa. Crystallizer koporo poleiti ke liboto karolo ena "pelo", holim 'a poleiti ea koporo e ka ho toba le tšepe e qhibilihileng, le khohlano le holim' a poleiti ea koporo e tota ka mora tšepe entsoeng ka ho qhibilihisoa e ile ea tiisa ka khetla letlapa, mmoho le ts'enyeho ke slag sireletsang, ka hona, le koporo poleiti holim tla lokela ho hanyetsa le utloahalang la ho petsoha mogote, apara le ts'enyeho. Lekapa crystallizer koporo etsoa ke Anhui Taier holim Engineering Technology Co., Ltd. ke barbotage manganga ho mocheso phahameng, apara le ts'enyeho hore o entsoe ka HVOF e tsoetseng pele, le metsoako e ka sehloohong ke lits'epe tse kopantsoeng phahameng mocheso kapa lits'epe tse kopantsoeng phahameng mocheso + letsopa le lintho tse ling thepa. The thepa e babatsehang ea lintho tse bonahalang tse barbotage etsa bonnete ba hore poleiti ea koporo ka sebetsa ka lebelo le phahameng kotokaka le chelete kakaretso ea tšepe sebelisoa ka nako e 'ngoe e haholo ba ntlafala, fokotsa litšenyehelo ka kakaretso bakeng sa tshebetso ya thepa mosebedisi le keketseho tsa khumo unit trust.

| boemo Tšebeletso: | Mocheso oa holim'a kopana le mokelikeli tšepe ≤500 ℃ | Barbotage thulaganyo e: | HVOF / Remelting |

| Hloleha mokgwa wa: | Tsofaleng, khoa, ts'enyeho | Barbotage lintho tse bonahalang: | Apara manganga motsoako |

| ditlhoko Performance: | Apara ho hanyetsa, ho hanyetsa ts'enyeho, ntle mogote conductivity | Bophelo pontshi: | Ntlafala ka makhetlo a 4-6 ha e bapisoa le sa electro-galvanized Ni |